You will need

- Sewing machine

- Shuttle

- Spool

- Thread

Instruction

1

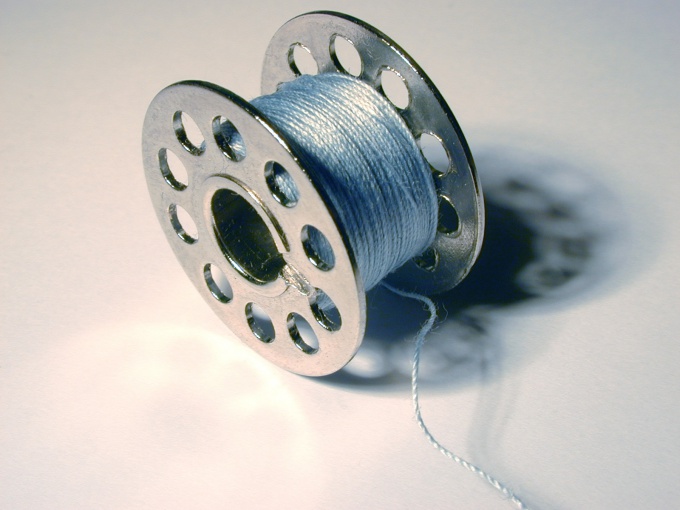

Wind thread on the bobbin. This can be done both manually and on the sewing machine. Manually — just loop the thread turn to turn. Try to do it smoothly, without loops and knots. The bottom panel of the sewing machine has a special pin, exactly the same as the one on which you installed the coil. Place it on the bobbin. Unwind from the coil a bit of yarn and wind them on the spool. This is to the thread in case of a mechanical winding from slipping. Then turn the handwheel. In this case, the thread will be wound on the spool and the needle bar remains motionless. Turn the handle of the machine or touch the pedal. Make sure that the spool is spinning in the same direction in which you have already started to wind thread.

2

Tear off or cut the thread. Remove the spool from the pin. Flywheel put in its original position. Raise the needle bar to the top position.

3

Remove the Shuttle. It can be horizontal and vertical, but fill it almost the same. Consider the Shuttle. You will see that from the outside it has a slanting slot covered by a metal plate, and inside the pin. To pin put the bobbin in. A winding direction of the thread must match the direction of the slot, otherwise the thread will be torn, and spool very quickly jump out of the Shuttle. Insert the thread into the slit and pull it a little. It should move freely.

4

At the bottom of the Shuttle with the external side you will see another sharp ledge. Look at the Shuttle devices. There you will see a groove, which is shaped like the projection is seated in the groove. A little pressure on the bottom of the Shuttle into the Shuttle device. If the canoe stood up correctly — you will hear a light click.

5

Now you need the bobbin thread to pull it out. This is done using the upper thread, which you have, of course, tucked and inserted the needle. Raise the foot. Lower the needle holder with the needle, twisting the knob or pressing the foot pedal. The lower thread must cling to the top and climb out, forming a small loop. Pull the loop and slightly pull out the thread.

Useful advice

Before you pull out the lower thread to check that whether the inserted needle.