Instruction

1

Prepare sewing machine for operation. Position the needle to its highest position using the flywheel. Pressure foot lift. The needle position in the needle clamp, and secure its screw.

2

Choose the right thread, given the color and size. To line get quality you need to use the top thread size bottom more. Install coil rod. Position it on the spool of thread.

3

Pull the thread from the spool to the thread guide, after you pass between the washers of the tension regulator. If the thread passed correctly, washers are to click. Continue to stretch the thread through the thread take-up hook.

4

Slide the thread into the thread guide located on the needle holder. Pass the thread into the eye of a needle. To easily thread a needle, use nettodental.

5

Pull the thread to check whether it clings for the elements of the sewing machine. Poorly polished details can sometimes cut the thread. Not worth tucked the string to pull too hard because this can break the needle.

6

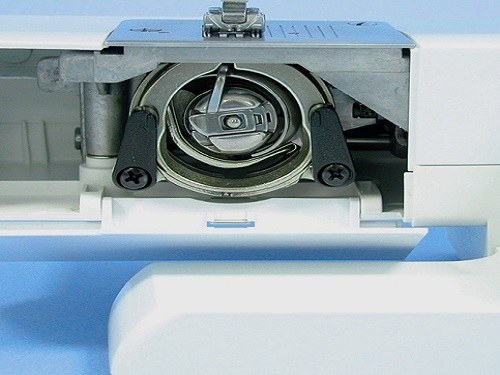

Fill up the lower thread. Slide the sliding plate and remove the spool cap. Remove it from the Shuttle, by following the special latch. The finished bobbin of thread insert in cap. Pull the thread through the slot, and after the tension spring on bobbin case cap.

7

Pull the thread to check whether it is easily unwound. Put the cap from the hook on the rod of the Shuttle. If the cap is properly sat down and fixed, should be a snap. The process of the latch cap to the hook should be spring loaded.

8

To pull the lower thread in the plate, lower the needle into the hole, holding the end of the upper thread. With the rise of the needle will come out the bottom to the top (Shuttle) thread in the form of loops. Pull both threads under the presser foot from himself. Sewing machine is ready for operation.