You will need

- A metal cable, a chain or wire, rebar, grinding machine

Instruction

1

The first thing to note is that the Damascus steel in the shop not to find. As such there is only the concept of "Damascus steel". Actually this is not the steel and forging method. Therefore, the phrase "Damascus steel knife" means that it was forged in a special way.

2

So, let's create a knife. Since swung to Damascus, just say that it's pretty expensive. But our Russian land, you can find material that is perfect for the job.

3

One of the most popular is the Damascus of the cables. The metal from which made cables, allows to obtain a fairly high-quality blade material, but at the expense of big picture does the increase of cutting properties.

4

No less popular and well-known materials such as chain. Mainly used chain of chain saws, chain or motor gasoline engines.

5

However, despite the apparent diversity, it is worth noting that these materials are suitable for the manufacture of blade of Damascus, very little. So often we have to look for new material, experimenting in order to get a new pattern on the finished blade. And one of the successful experiments of this kind was the Damascus of the coil wire. On it and focus.

6

The first thing you need to figure out the chemical composition of the wire. This is done in order to find out whether it is welding forge welding. Plus, you need to figure out the approximate amount of carbon. Such inquiry is necessary to learn, whether you take the finished blade is hardened. Though at first glance it seems incredibly difficult, but it is actually simple. Verification by spark.

7

To do this, bring the end of the wire to the rotating disk of a grinding apparatus. If you receive the average density of the sparks of orange – you can work with a clear conscience. If the number of sparks and the color of the other species, especially do not worry. It's only slightly affect the pattern of the finished blade and its physical properties. But in General it is the same knife, which we so hard to move.

8

The above-described variant check spark allows you to determine the approximate carbon content. If the sparks correspond to the first description, the carbon content is about 1%. This means that the metal will take a decent hardening.

9

Next, you need to be annealed in order to facilitate further processing. Heated to the austenitic transformation and allow to cool. Thereafter, the wire becomes soft.Then you can create the workpiece. The wire is pressed and welded thereto, the handle of the valve. Then this "blank" is heated in a furnace to about 800 degrees.After heating liberally sprinkle borax. It is needed for dissolving scale and metal protection from oxygen. Now produce the welding.

10

When the workpiece is ready, you need to forge the blade. This delayed the body, the nose of the blade and the shank. Then the blade is polished and trim the ends. Welded shank and are laid out future runs. After all this, again perform heat treatment. Is the normalization for the crushing of grains of the metal, and is hardened. The heated blade to the quenching temperature and drop in heated to 70 degrees oil. Then heat to 200 degrees and hold for two hours.

11

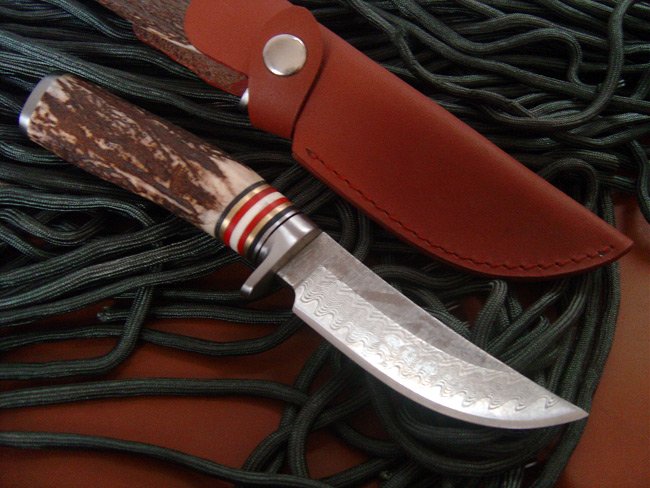

It remains only to Polish the blade is clean and etch it into a five percent solution of ferric chloride. It is necessary to show a picture. The end result is a beautiful Damascus steel knife, forged with his own hands.

Note

This is only a superficial explanation of how to forge a knife of this kind. If you have the desire to seriously address this, we first need to find the drawings of the knife, the material and the place where all this can be done. For cooking in the oven it clearly can be done.