You will need

- - packing the valve;

- - oxygen-propane torch;

- tanks to the burner;

- and measuring devices;

- - a set of tools.

Instruction

1

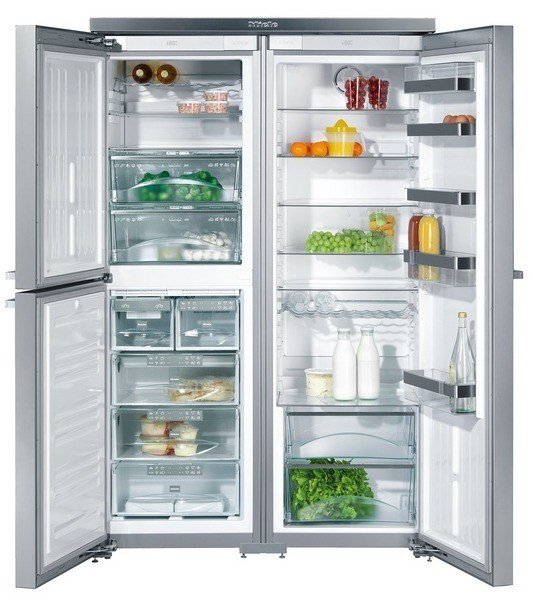

Free refrigerator - remove all food, remove shelves and drawers. Unplug the refrigeration unit from the electrical network and expand it in such a way to get free access to its rear side. It was there, in a niche on the metal traverse is the compressor.

2

Lift the compressor. Carefully bend the tube and slide the compressor forward to see 5-7 For steel pipe is not broken, if it should proceed with the greatest caution.

3

Will nantokite filling up and remove the freon from the cooling system. For this it is necessary to pinch the capillary tube and turn on the compressor of the fridge for 3 minutes. During this time the freonpresent in the unit, percacets in the condenser. Take a special piercing valve and hook it up to the filter-dryer. Connect a hose to otvaloobrazovanija tank followed by a filter-drier by connecting the selection valve. Open the cylinder valve for 30 seconds and collect the freon. Close the device.

4

Solder in place of the filling tube is copper. The length of the copper tube should be 6 cm, diameter - 6 mm. Soldering parts of the refrigerator can be done with a soldering iron, or air-propane torch.

5

Make the incision into the capillary tube. The incision should be placed at a distance of 3-5 cm from the filter-dehydrator. Break off the tube at the incision. Unsolder the filter drier from condenser and remove it.

6

Desolder the compressor from the suction and discharge tubes. Clean the old solder tube of the refrigerator and install a plug.

7

Remove the plugs from the new compressor. Wire connections of the compressor with the tubing of the refrigeration unit. Install filter drier to condenser, and insert a capillary tube. Solder the compressor. Carefully inspect the soldering joints on all sides with a mirror. Make sure that soldering is produced evenly and not left neproblem.