You will need

- - a set of tools;

- tester;

- - an air compressor.

Instruction

1

To check the solenoid, take the tester and switch it to the mode of operation of the ohmmeter. With the help of the technical documentation for the vehicle find out where the solenoid is installed between the car computer and ground or between the control unit and a current source. Another important point: what is the normal state of the solenoid valve is open or closed.

2

Using an ohmmeter, measure the electrical resistance, joined to the contacts of the solenoid. Its resistance to cold and hot, look in the instruction manual of the car. Be sure to check the circuit of the solenoid for a short. For this purpose each of the contacts close to the vehicle body using an ohmmeter. If possible, dismantle and rinse solenoid in gasoline in order to get rid of the particles accumulated in the passages and the valve. If he does not understand, just replace it.

3

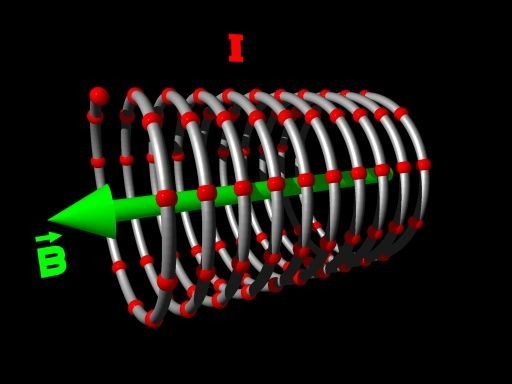

Because in the solenoid generates a magnetic field powerful enough, it may accumulate micro-particles of metal which clog the channels and the valve. In the result, the moving parts are unable to move normally. To check the channels of the solenoid and hydraulic valve use a compressor with compressed air. When you do this, be sure to check the documentation, open or closed, the valve in the normal state.

4

Closed in the normal way solenoid conduct a simple test. Unplug it from the power supply. Then send him a stream of air under pressure. It should not be through its output channel. Post on the solenoid voltage. The air must pass through the output channel. In this case, the solenoid can be considered serviceable.

5

For normally open solenoid, the situation is reversed. When you disconnect it from the power supply it needs to pass air under pressure, and when the current is switched on must lock the channel, and the air it will be.