Instruction

1

To test inter-turn short-circuit, use an ohmmeter. Connect the device and take readings. Verify the results with a given resistance value. Remember that by reducing the winding resistance through the contacts of the regulator begins to pass current greater permissible value (often between the contacts skips spark).Please note, if the power generator has fallen sharply, the battery is stopped to show the level of charge, then most likely there is a break in the circuit phase windings of the stator. If you broke both phases, the generator will not work at all.

2

If you have already disassembled the generator, test the inter-turn short circuit can alternately connecting to the battery phases, closed on the bulb. The lamp will not illuminate if the circuit is open.

3

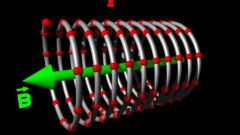

Use flaw PDO-1 this unit has an induction and receiving-signal devices. When checking the winding flaw install so that the groove between the teeth of the stator core located between the air gaps of the core and receiving the signal and induction machines. Connect the induction coil of the apparatus to the source of AC or DC voltage of 12 V. In case of a malfunction of the circuit, a neon lamp PDO-1 will be steadily lit.Remember that the detector can work continuously for not more than three minutes.

4

Use the electromagnet and the steel plate. The method is simple and old, but has not lost its effectiveness. Place the steel plate on the reel but fix it if you have closed coils, the plate will be attracted to the grooves where the damaged section.