Instruction

1

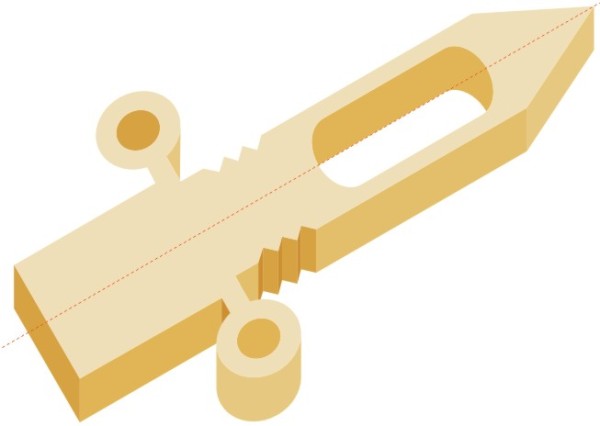

The knife can be manufactured by cutting individual parts from the sheet of plywood medium thickness. For this paper make stencils of parts of a knife: one piece for the blade and two parts to the handle. Then attach the stencil to the plywood, draw and cut parts of a knife. For fastenings make small holes at the beginning of the blade and from both ends of the arm parts. All parts are held together with metal pins or all kinds of materials.

2

Another option is making a knife out of wood – knife-balisong from wooden Popsicle sticks. Balisong – a knife-a butterflyknife with a blade that is hidden in folded position in the handle, formed by two longitudinal halves. When opening these halves revolves 180° in the opposite direction of the blade exposing the blade and forming the handle.

3

You will need 4 thin Popsicle sticks, 1 Popsicle stick, a few wooden toothpicks to connect the parts. First of all make a drawing of the knife. Next on the drawing, cut the unnecessary parts of Popsicle sticks.

4

Then drill in the appropriate locations on the finished parts of the knife holes of approximately 2mm is a hole for mounting arm, coupling it with a blade and latch. Then assemble the knife using toothpicks.

5

They should loosely be included in the hole, because then you will be strengthened with glue. Stick a small Popsicle stick to the toothpick. This knife blade, it should slide easily. Next, connect all the parts and seal the toothpicks. The knife is ready, you can proceed to the games.

Note

However, this is not the only option. You can meet wooden knife, knives from a special type of plastic, ceramic knives. However, this does not apply to knives of wood or plastic. Meanwhile, you can purchase this knife from a strong enough wood or a special plastic.