Instruction

1

The intended procurement is for onion scratch in the winter time, it is desirable that the day was frosty. If you don't want half a day to roll through the snow, we recommend you to identify the tree in summer. Harvesting onions should not have large knots and growths, as well as mechanical damage. Workpiece length must be greater than the expected length of the bow to 30 cm to Remove the bark from a workpiece is not necessary.

2

Cover the ends of the workpiece with oil paint. Wood needs to dry evenly to avoid internal defects of the material. Drying should occur in an upright position at room temperature. Two months for drying is sufficient.

3

After drying, proceed to the manufacturer of the bow. With an ax and a sharp knife give the bow the desired cross-section throughout its length. It will depend on the thickness of the workpiece. The section can be lentil-shaped or rectangular.

4

At this stage the bending of the bow. Some manufacturers have resorted to soaking the workpiece in various infusions and solutions. But simple steam treated wood has all the necessary for us properties.

Shoulders the bow, you need to steam the material gains plasticity and easily takes a bend, you specified. To steam both shoulders, it is recommended to bow and then dried uniformly throughout its length.

Shoulders the bow, you need to steam the material gains plasticity and easily takes a bend, you specified. To steam both shoulders, it is recommended to bow and then dried uniformly throughout its length.

5

After steaming the bow is placed in the berth of a curved form, to enable drying to take the desired shape. The slipway bow to dry for about a week. Then the bow is removed, and its ends are made for the subsequent donning of the string (cut the notch under the loop of string).

6

During Stripping the bark exfoliates from the back of the bow, it can gently separate the wooden knife, taking care not to damage the wood fibers. Now the bow must be protected against drying out and moisture. To do this, soak it with hot wax or melted fat.

7

The string is recommended to wear directly before firing and to remove after the application of onions. To preserve onions make the case. It is recommended to store the bow in a vertical position at room temperature and moderate humidity.

8

To make arrows, use pine boards or bead. Wood must be seasoned. Stock thickness at least 2 cm Blank arrows should not have knots, fibers should be parallel to the length of the workpiece. When making arrows you will need a saw, plane, file and sandpaper. Boom length is determined individually, taking into account the tension force of the bow and your physique. Approximate length – 70-80 cm

9

Measure on the Board the length of the boom. Cut the blank from the Board. Bring the workpiece to a thickness of 1.5 cm planed. Mark the Board width into pieces of square section and get along. With file give the blank a hexagonal shape, and then sandpaper to make a round cross-section. The arrow shaft is ready. The thickness of the arrows should be 8-9 mm.

10

In the manufacture of feathers, take three crow's feather. Cut them along the groove. Cut the rod to the beginning of the pile. Cut with scissors from the pen tip, the bristles about 0.5 cm (to fast-tail). Install the feathers on the arrow shaft at an angle of 120 degrees to each other. Tape the feathers with thread, with its turn to turn.

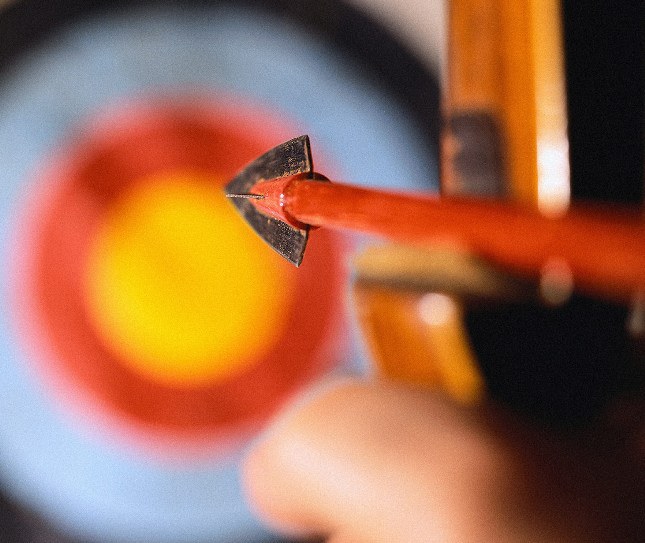

11

An arrowhead fabricated from a metal plate of triangular shape with a tail equal in width to the thickness of the arrows. At the front of the shaft make a recess for the shank. Insert the tip of the tail in the recess and screw thick nylon thread turn to turn.