Instruction

1

Fiberglass is often used for the treatment and strengthening of wooden structures. The process is fairly time consuming but really gives the tree the necessary strength. First of all, the design is applied adhesive resin so that completely cover the entire required surface. After the resin in the wood hardens, zashpaklevyvayut all defects such as cracks or bubbles, bumps, not provided for in the design. A perfectly flat surface for successful operation is not required - as long as it was dry and clean. Then on a dry surface is glued to the fiberglass. You need to cut pieces of desired shape, to adjust them and fix to a suitable location. After that, the surface of the fiberglass cover layer of resin. Put it on limited areas and spread with a roller in all directions, banishing the air bubbles. After drying, you can stick another layer or even to give strength.

2

It is possible to do designs directly from fiberglass. To do this, make a matrix to create one which uses foam or foam sheets. The finished matrix wound layers of cling film, you can use foil, ordinary paper. Fix with masking tape. A thin layer of epoxy resin applied with a brush, being careful not to use too much. Imposed on top of the fiber glass is spread over the surface, cut or tuck all the excess and then cover the top with epoxy. This procedure is repeated 3-4 times depending on the required thickness and strength, and then well dried. The surface after drying should be sanded with coarse sandpaper, changing it gradually into smaller ones. The final stage through the design skin-nulevkoy. You will then need a special coating on the fiberglass, after this final stage of painting, the different decor and, if necessary, coating.

3

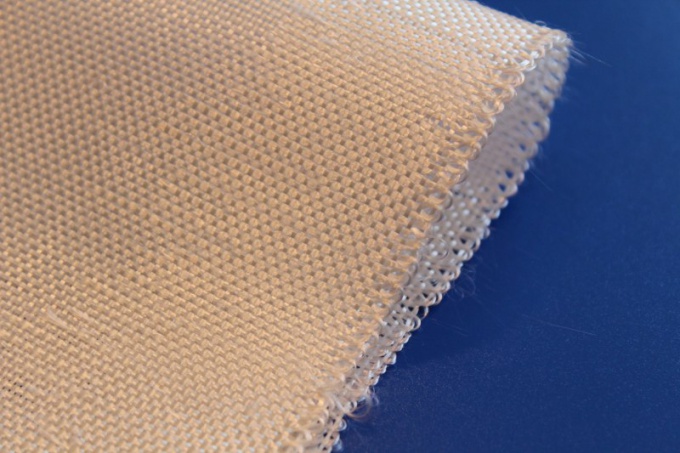

Competently fabricated parts and frames fiberglass have a strength of more steel, if the right to implement all recommendations in the work. Before starting work, fiberglass degreased. To do this, soak a cloth with gasoline, alcohol or solvent. These substances are capable of dissolving often the particles of paraffin in the fibers of the fiberglass. After. as the procedure is completed, the material needs to dry completely. When you choose fiberglass for work, you need to consider its density, since the higher the density, the harder it is to work with small parts. If the density is low, you need to consider a number of features: the lower it is, the more layers you will need for the desired thickness of the product and the more time spent, as before applying layer you need to wait until dry previous.