Instruction

1

Develop and make the shape of a boat. To do this, first you need to make the drawings on paper, and then, according to them, assemble the desired size. Then you need to make a shape for boats made of fiberglass. To create it you will need to cut all the needed parts from wood. You should make every effort to wooden form was literally perfect. If you do not belong to the finishing mold in an extremely responsible manner, then it is possible that the boat will have various flaws and defects.

2

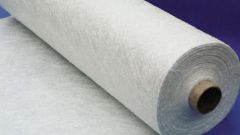

Cover the form with a special paint for outdoor use, which has high strength and is aged for about eight years in operation. Do a fiberglass boat. For this you need to add a certain amount of fibreglass in a plastic resin. Fiberglass is an ideal shipbuilding material since it is glass, which is represented in the form of very thin, flexible fibers that do not burn, do not stretch, and does not give in to rot over time.

3

Place the fiberglass into every crevice, every nook and cranny of your form. This should be done very gently and carefully, because otherwise you can not have anything to do with the structural defects of the boat. After the fiberglass has accumulated sufficient heat, it will harden.

4

Roll top fiberglass roving material. It enhances all the properties of the fiberglass and makes it more resistant. In those places where then you are planning to attach the equipment, you need to place the wooden parts. To protect them from the damaging effects of moisture coat the parts with fiberglass.

5

Pull the casting from the wooden form when one hour passes. With the aim of raising the hull of boat use leverage. Cut out the holes for the mechanics. Insert the motor, wiring, and piping system. Swipe a series of tests that will allow you to make sure that the boat is waterproof.