Instruction

1

Fiberglass is produced of assembled in parallel bundles of optical fibers or from glass fiber. The last is made usually of glass type "E", in which the content of alumina ranges from 12 to 15%.

2

The considered material has unique properties:

- resistant to fire, corrosion and chemical factors;

- able to withstand large temperature changes from -200 to +550оС;

- durable in use;

- is an environmentally friendly material that has a high resistance to decomposition.

- resistant to fire, corrosion and chemical factors;

- able to withstand large temperature changes from -200 to +550оС;

- durable in use;

- is an environmentally friendly material that has a high resistance to decomposition.

3

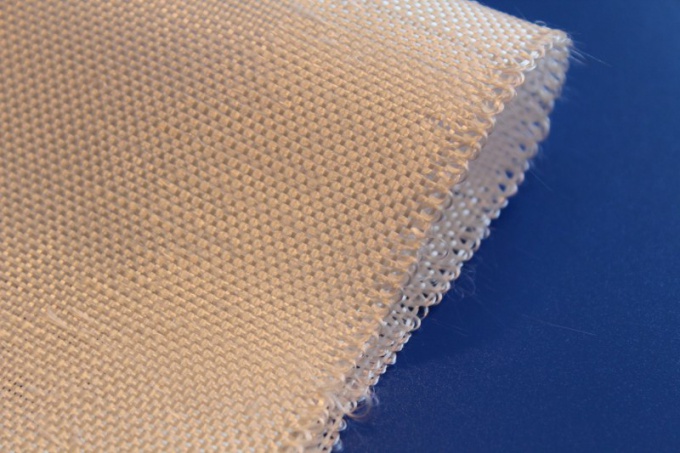

All fiberglass klassificeret on the thickness of the yarns and type of weave. In accordance with the latest classification of the plain, satin, twill and multiaxial fabrics made of glass.

4

Satin fiberglass are different from other types of higher elasticity and relatively low density. Both of these factors allow the use of a satin fiberglass products for the manufacture of complex shapes.

5

Twill weave is characterized by the fact that overlapping filaments are at an angle of 45 degrees. Because of this, the finished product seems trubchanin. Twill fabric is more dense than satin, because it is commonly used where you want to create a more or less smooth surface.

6

In multiaxial fabrics made of glass fibers can go in 3 or more directions.

7

But fiberglass plain weave have the highest density. Often, this material is also called stekloreza. Weave the yarn in it is at an angle of 90 degrees in one direction. The strength characteristics of the cause and scope of this material – reinforcement of heavily loaded sections, plastic, simple form.

8

To the consumer the fiberglass comes in rolls but can be cut into individual elements.

9

Fiberglass are used in many sectors of production: for the production of fiberglass as a reinforcing element, in engineering and shipbuilding, the production of goods for rest and sports. Fiberglass is used actively in design and construction. But this is not all areas of use glass cloth.

10

Keep material manufacturers recommend in a dry place with low temperature. The relative humidity in the warehouse should be maintained at around 75% and the temperature should not exceed 35oC. Transportation fiberglass to the place of use must be carried out in sealed original packaging.