You will need

- spanner 13 mm,

- - wrench 17 mm

- - mount,

- - the range.

Instruction

1

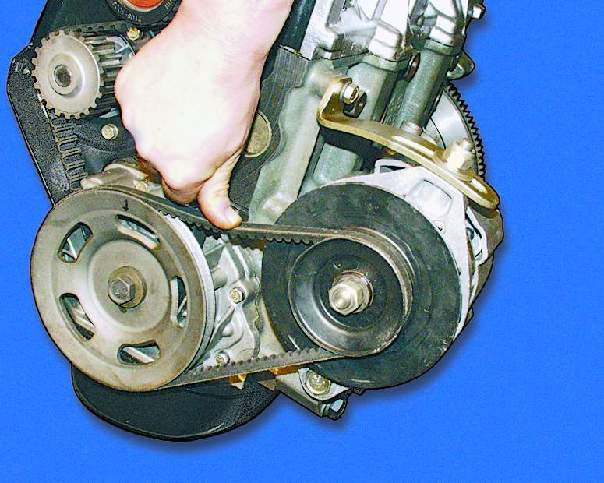

To verify correct belt tension, you need to put over the pulley on the alternator and water pump any flat, metal object such as a narrow mount. Then you want to press your hand down on the center of the belt, then measure with a ruler deflection, which is when the force equal to 3-4 kg, should not SAG more than one inch. If the test measurement does not correspond to the norm, it is necessary to adjust belt tension of alternator drive belt.

2

To solve the problem is the loose nut of fastening of the generator to a tension lath and bolt the lower mount to the engine bracket.

3

Then pry the alternator away from the engine, and in this position is fixed by tightening the nuts on the tensioning strap. Then check the degree of belt tension.

4

If the tension meets the technical requirements, then the final tightening of the upper and lower mounting of the alternator on the engine.

5

In cases where the tension of the timing belt didn't execute properly, then mandatory to repeat the process.

Note

The correct tension of the belt drive generator and water pump ensure a comfortable operation of the vehicle over a long period of time.