Instruction

1

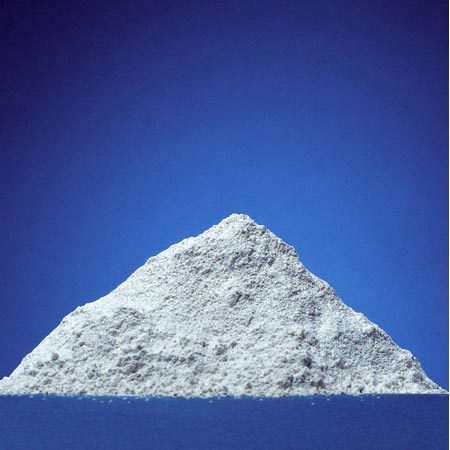

Gypsum is sold in any hardware store, sometimes the plaster can be replaced with white finish putty, but it cures slower. For one of the plaster castings made of rough plaster mold with a soft model, used it only once since her break after drying. To do this form is needed in those cases when there is no need to make products EN masse, or else the product is very complex. Pure forms are used repeatedly for casting of products of cement or gypsum. Semifinished forms removed from the soft models.

2

Forms of gypsum can be easy, medium and difficult. The manufacture of forms of bulk product or sculpture is no different from conventional molding. Plaster forms are hygroscopic, they should be carefully permeate separation system based on wax or paraffin.

3

To cast a form of plaster, mix it with water to the consistency of liquid sour cream, pour, wait 10-15 minutes, the plaster will gradually harden. The cured workpiece, remove, remove excess and put in a warm place for a day for final drying. When the blank has dried, remove the excess again, scuff fine sandpaper the entire surface. After that, take a stain for wood, mix it with water and dip it in the finished product for 10 minutes, then remove the workpiece and allow it to dry a bit.

4

A damp cloth wipe all the convex part, the end result is that all exposed parts will acquire a lighter shade. If the capacity is not large enough to be able to put there the product of the billet cover the stain with a brush.

5

Producing hollow product, a solution of plaster make more liquid, the form in plaster casts and don't let go for 15 minutes. The form needs to shake all the time in order for the plaster went on the walls evenly and freeze. In the manufacture of decorative tiles for interior design, gypsum should be given more firmness by adding to the composition a little slaked lime. After the molded form has dried, it is impregnated with a solution of sulfate salts.

Note

Slow setting gypsum mortar, you can use the introduction in solution of bone glue or plasticizer

Useful advice

If plaster to give a greater hardness, the finished product will look like made of plastic.