Instruction

1

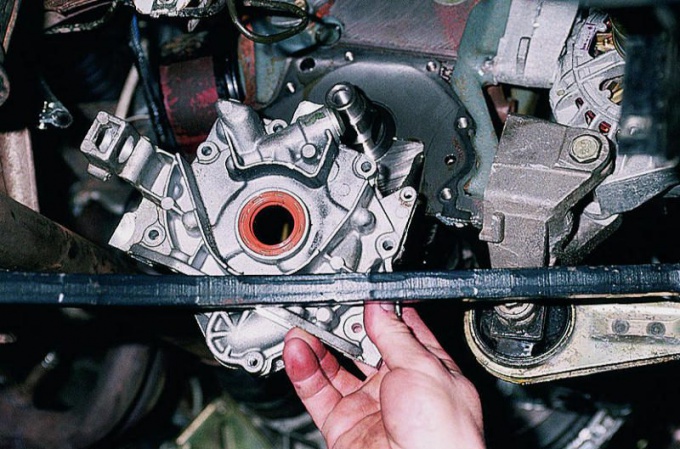

First, remove the oil pump. To do this, place the car on a lift or driving on a viewing hole. Disconnect the battery leads and carefully drain the oil from the engine. Unscrew the nuts that attach the forward engine mount to the crossmember. Remove the engine crankcase and pump.

2

Fasten the oil pump and remove the bolts, then remove the oil pressure valve and the suction inlet. Then clean all parts with petrol, then dry with compressed air, carefully inspect the cover and body of pump for cracks, and if necessary, replace them.

3

Using a set of feeler gauges check the clearance between teeth of gears, and between the walls of the housing of the pump. These distances must not exceed a value of 0.25 mm. If valid values are not, replace the gear and the housing of the pump. Inspect the oil screen and oil pan.

4

Measure the clearance between the plane of the housing and the ends of the gears. Its value should not exceed 0.2 mm. Also guide the measurement between the axis of the driven gear and the pinion. Remember that in case of any deviation, necessary to replace worn parts.

5

Carefully check the valve for damage and contaminants, sediment that can lead to galling. Pay attention to finding corrosion. Also remove all nicks and burrs that will lead to lowering of the pressure in the system. Check the elasticity of the valve spring and assemble everything in reverse order, first installing in the housing of the pump shaft and gear, and then the cover.

6

Lubricate all the parts of the pump with engine oil, which will prolong their service life. After Assembly, rotate the lead roller with your hand. Pinion should rotate smoothly and without effort.