You will need

- power supply 12-16 V or 24 to 32, wire

Instruction

1

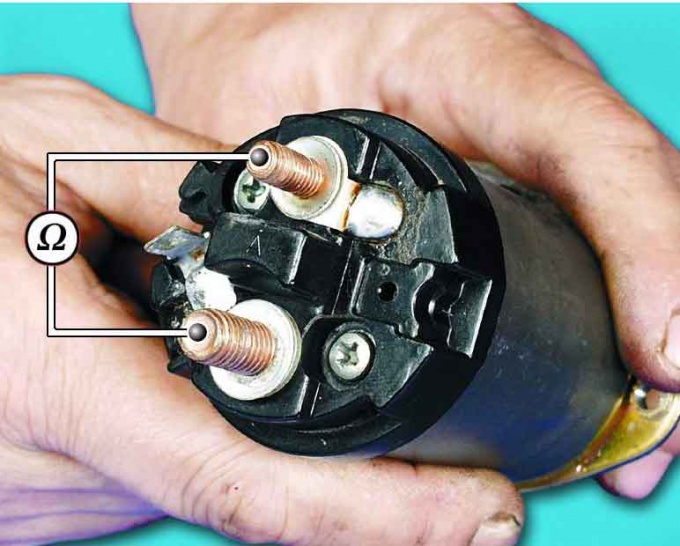

Remove the car starter from the engine. To check out the retractor relay starter, connect the output retractor relay "50" with the positive terminal of the battery, and the housing of the starter with the negative. A healthy traction relay of a starter the anchor will push the drive gear out the window of the front cover with a distinctive click. Retractor relay performs two important functions. With a lever actuator (plug of the starter) with one-way clutch causes an engagement of the latter with the engine flywheel of the vehicle, and closes the contacts on the front side, thereby providing the current flow of the circuit to the stator of the starter. The typical failure of the retractor relay - scorching contacts, jamming of the armature due to corrosion or dirt, breakage or burnout of the winding.

2

Install between the gear and the restrictive ring gasket with a thickness of 12.8 mm and turn on the relay. Take the device and check the switching voltage of the relay. It should not exceed 9 V At an ambient temperature of 20±5° C. If the voltage does not match, it indicates a fault or a relay, or drive.This validation scheme is applied for starters, the ST-221 manufactured up to 1983, when he established a single traction relay. Have a starter with such a relay should also test the strength of the current. It should not exceed 23 A.