You will need

- Essential tools include:

- - soldering iron (soldering station),

- - pliers

- - tweezers

- - an x-ACTO knife.

- Materials:

- - solder (tin)

- - flux (rosin or solder paste).

- For safety and greater convenience in the manufacture of tinning used a wooden plaque.

Instruction

1

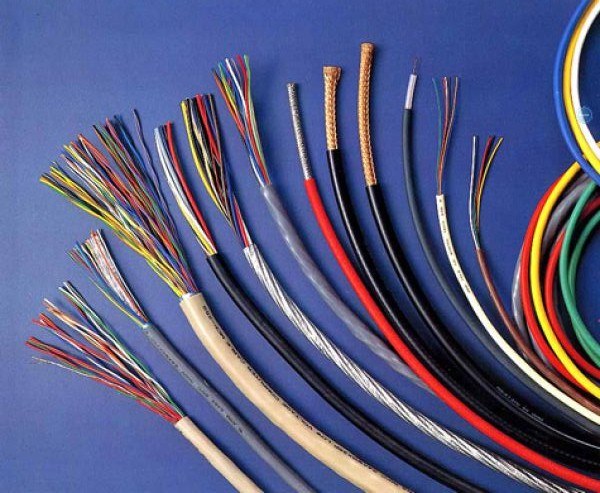

Maintenance of wires begins with the removal of the insulating layer from the end of each wire. To do this, take a utility knife or tweezers and trim in a circle the insulating layer of each wire, then remove the insulation. The clearing can be up to 30 mm, but usually the length of treatment is determined by the way in which will connect the wires.

2

Next to remove metal cores of oxides and residues of the insulation wire trimmed with a knife to Shine. If the wire is stranded, then it dissolved like a fan, and trimmed every transactions separately. After Stripping the end of the wire again sbivaetsya.

3

Turn on the power grid the soldering iron and heat it to the desired temperature. The thicker the wire, intended for tinning, the stronger must be the soldering iron. Also, before using a soldering iron, check the purity of its sting. If there is a need to clean it from oxides with a file or needle file. Once tipped soldering iron warms up, it is recommended to RUB the tip of his stinger on a wooden plank.

4

Apply the soldering iron to the cleaned end of the wire for its heating. Next, touch the soldering iron rosin and a piece of solder so that it is evenly distributed over the entire surface of the tip. Soldering iron tin bring to an end the heated wire and with light pressure RUB the tip across the surface of the bare harness. If the wire was sufficiently warmed, the layer of tin evenly. When tin or rosin is not enough for complete tinning the cleaned surface of the wire (spreads quickly or evaporates), typed the following portion of the solder.

5

The wire should keep a pair of tweezers or pliers to keep from burning hands. If the wire is difficult to service (made of steel or other refractory material) should be used instead of rosin solder paste or a special acid you can substitute tin for better quality solder.

6

Upon completion, you should make sure that the stripped end of the wire completely and evenly covered with a layer of solder. If you are badly treated, the tinning should be repeated.

Note

Stripping wires is not necessarily carried out mechanically, you can use a quality solvent (Acetone or white spirit). To do this, moisten a lint-free rag in solvent and wipe each wire. If necessary, you can leave the "wrap" for 10-15 minutes, then start maintenance.

Useful advice

The solder was located on the surface of the wire evenly, hold the soldering iron tip up, and the wire - ends down.