You will need

- You'll need: a vise, a file, taps, dies, tap wrenches, machine oil and desire.

Instruction

1

Thread is, in essence, a spiral groove cut on an outer or inner cylindrical surface. Mainly used to connect different parts with each other. In engineering can be used to convert translational motion into rotary and Vice versa. There are two types of threads such as metric, with the profile angle 60o and pipe with angle 55о.

In a metric thread diameter and thread pitch measurements are in millimeters. In the designation of a metric thread is used alphabetical and numeric labelling, such as M8x1. 5. The number eight corresponds to the thread diameter, and 1.5 indicates the thread pitch, the distance between turns.

In inch thread, the measurements are conducted in inches and the number of turns per inch. One inch is equal to 2.54 cm To the inch example thread record 1 1/4".

In a metric thread diameter and thread pitch measurements are in millimeters. In the designation of a metric thread is used alphabetical and numeric labelling, such as M8x1. 5. The number eight corresponds to the thread diameter, and 1.5 indicates the thread pitch, the distance between turns.

In inch thread, the measurements are conducted in inches and the number of turns per inch. One inch is equal to 2.54 cm To the inch example thread record 1 1/4".

2

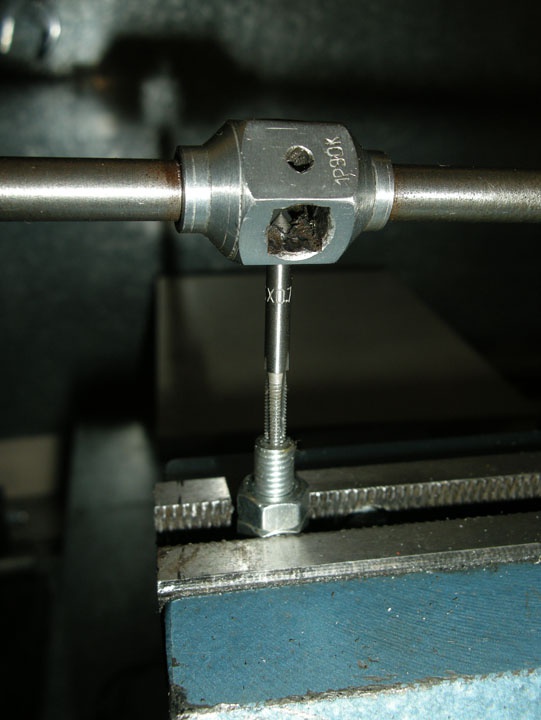

To cut external threads you need to take a die of desired size to prepare the workpiece, and in particular, to pick up a workpiece of a particular diameter. The diameter of the workpiece for threading is determined by the tables. In practice, for cutting, for example, a thread diameter of M6, required rod cross-section of 5.92 mm, that is approximately one-tenth of a millimeter smaller for the thread M8, the workpiece should have a diameter of 7.9 mm.

Here's an example excerpt from the table of diameters for metric threads:

Thread diameter/shaft diameter (mm) - 5/4,92; 6/5,92; 8/7,9; 10/9,9; 12/11,88; 16/15,88; 20/19,86; 24/23,86

After the selection of the workpiece, it is clamped in a vise, a file is removed from the end of the chamfer for proper setting of the dies, and rotary-clamping movements and threading do not forget to lubricate the part with engine oil.

Here's an example excerpt from the table of diameters for metric threads:

Thread diameter/shaft diameter (mm) - 5/4,92; 6/5,92; 8/7,9; 10/9,9; 12/11,88; 16/15,88; 20/19,86; 24/23,86

After the selection of the workpiece, it is clamped in a vise, a file is removed from the end of the chamfer for proper setting of the dies, and rotary-clamping movements and threading do not forget to lubricate the part with engine oil.

3

The internal thread is cut by the tap. Pre-drilled holes must be smaller in diameter, you need thread. Extract from the table of diameters of drill bits for drilling holes are shown below.

Thread diameter/hole diameter (mm) - 2/1,6; 3/2,5; 4/3,3; 5/4,2; 6/5,0; 8/6,7; 10/8,4; 12/10,2; 16/13,9; 20/17,4; 24/20,9

For threading inside the part, you must have two of the tap, roughing and finishing.

Also hold the detail in cutting and rotational movements with slight pressure threaded tap draft, periodically lubricating the tap with engine oil, then make a finishing pass. Thread ready to use.

Thread diameter/hole diameter (mm) - 2/1,6; 3/2,5; 4/3,3; 5/4,2; 6/5,0; 8/6,7; 10/8,4; 12/10,2; 16/13,9; 20/17,4; 24/20,9

For threading inside the part, you must have two of the tap, roughing and finishing.

Also hold the detail in cutting and rotational movements with slight pressure threaded tap draft, periodically lubricating the tap with engine oil, then make a finishing pass. Thread ready to use.

Note

For more quality threads do turn of a knob 180 ° clockwise and then 90°. Due to this cut long chips and decreases the force on the knob.