Instruction

1

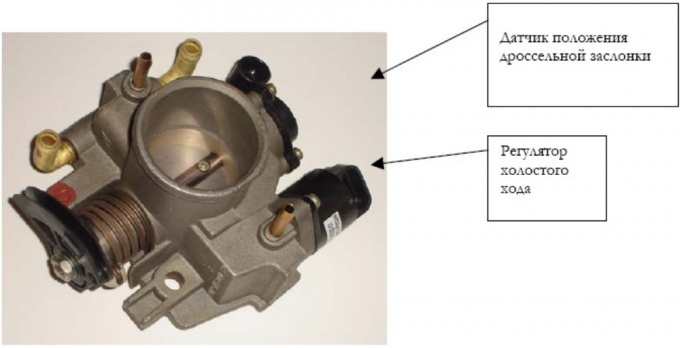

Turn on the ignition and look at the instrument panel. Take a look at the light "Chek". If it is not on, and the notification of any fault, raise the hood and Podlasie to the sensor provisions throttle flap.

2

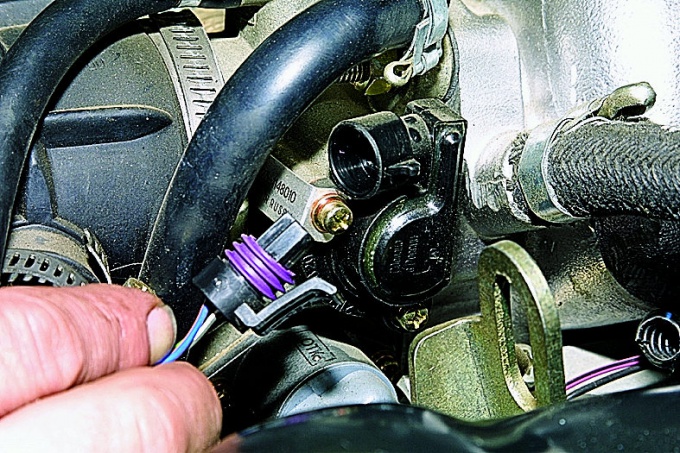

Grab a measuring device, preferably a multimeter. Check "minus". To do this, turn the ignition off and find the ground among the wires. Then you must make sure that the sensor is receiving power: turn the ignition on, locate the power lead. If both wires are found, it is very good.

3

Check the contacts to open idle. They are second from the top or bottom of the sensor connector throttle flap. Connect one wire of the multimeter and the second slide valve. If the TPS is configured correctly, at the slightest movement, the voltage scale of the instrument will change abruptly to a value on the battery.

4

If the voltage increases smoothly or at all costs, try to check the film of the variable resistor which is located inside the sensor. Connect the multimeter to the remaining wire, turn the ignition on and slowly move the flap, keeping an eye on the instruments scale. Here, jumps should not be, the voltage varies very smoothly. If there is a race, the engine will not operate properly.