You will need

- engine;

- capacitors;

- calculator;

- tools.

Instruction

1

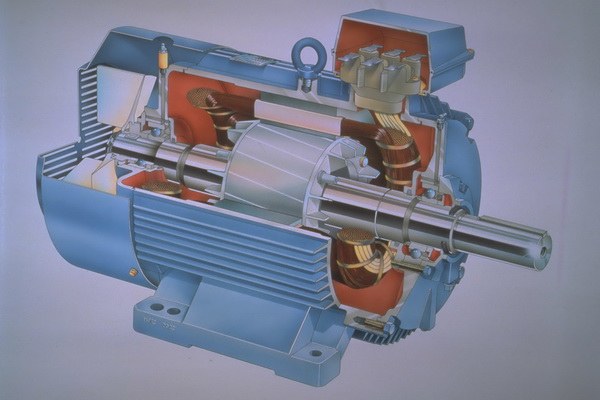

Carefully examine the engine. In that case, if it has six pins with the jumper, check the order in which they are installed. If the motor has six pins and not the pads, the pins must be assembled into two beams, and one beam is collected should be the start winding, and the second ends.

2

In that case, if the motor has only three leads, disassemble the engine: remove the pads from the cap and look in the windings the connection of three wires. Then disconnect between these three wires, probajte thereto lead wires and combine them into a beam. Subsequently, these six wires will be connected according to the scheme "triangle".

3

Calculate the approximate capacitance of the capacitor. To do this, substitute the values into the formula: Smcf = P/10, which SMCP is the capacity of a condenser in microfarads, R is the rated power (in watts). And just as important: the working voltage of the capacitor must be high.

4

Please note: if you include volt capacitors in a serial connection method, it "lost" half of the total capacity, but the voltage will double. Of a pair of such capacitors can be assembled battery of the desired capacity.

5

Connecting the capacitors, note their peculiarity: the fact that after disconnecting the capacitors for long time at the terminals remain voltage. Hence, these capacitors represent a danger to life, because too high a risk of electric shock.

6

Starting resistance Rn is determined empirically. To increase torque during starting of the engine, simultaneously with a condenser connect launcher (it is connected in parallel to working). The capacity of the starter capacitor is calculate by the formula: SP=(2.5 to 3)CP, where CP is the capacitance of the operating capacitor.

Note

Follow safety precautions when connecting the motor capacitor!

Useful advice

To prevent welding of silver contacts of the capacitor, make the plate start relay from coal or graphite brushes, and disable thermal protection relay.