You will need

- - metal brush;

- spray WD 40, kerosene, turpentine, rust cleaner or brake fluid;

- - screwdriver slotted or Phillips;

- - impact screwdriver;

- - hammer;

- - nail file or needle file;

- - drill with set of drill bits, tap;

- - special tools Alden 4507P;

- - safety glasses, gloves.

Instruction

1

Do not attempt to Unscrew a rusty screw with a countersunk screw or bolt without preliminary operations. So you can just strip the threads, and with the intention to Unscrew the screw or to Unscrew the bolt, you can't. Wire brush clean the parts threaded connections from rusting. Then treat them with WD 40 spray, turpentine, kerosene, rust cleaner or brake fluid.

2

It is possible for the best effects of these substances drench them in cloth and leave it for fastening articles 5-10 minutes to. If you do not get results, re-apply a good penetrating lubricant WD 40 on the threaded connection. Then easily Unscrew the problematic screw with a countersunk head, or other element threaded connections.

3

Try loosening naughty flat-head screws or bolts as would shake them from side to side. Thus the grease will be easier to penetrate deep into the threaded connection. Therefore, your attempt to perform such a task, to Unscrew the screw or to Unscrew the bolt, will be successfully resolved.

4

If the flat-head screws strongly stuck, use suitable slotted or Phillips screwdriver and try to twist it, gently striking the handle of the screwdriver with a hammer. You can use a percussion screwdriver. Insert it into the slot and strike hard with a hammer on the head of a screwdriver. The mechanism of a screwdriver would turn the screw. However, this screwdriver is not cheap.

5

Try to heat stubborn threaded connection using the soldering iron, boiling water, etc. At high temperature destroyed the mill scale and rust, preventing the unscrewing of fasteners. Just try to Unscrew the parts of the threaded connection should immediately, otherwise they will warp, which will complicate further the process of unscrewing.

6

If the details of the threaded connection has deteriorated as a result of external aggressive impact, or were originally of poor quality, try to extract them in the following way. Weld some kind of lever or nut to the exposed portion of the screw, bolt or stud and try to Unscrew them in one of the above ways.

7

Drill out very carefully without damaging the threads, damaged parts. First make a file or a needle file took to drink for a more accurate marking drilling position. Next drill a smaller drill hole. Taps cut new threads, insert the bolt and remove the remains of the fastener.

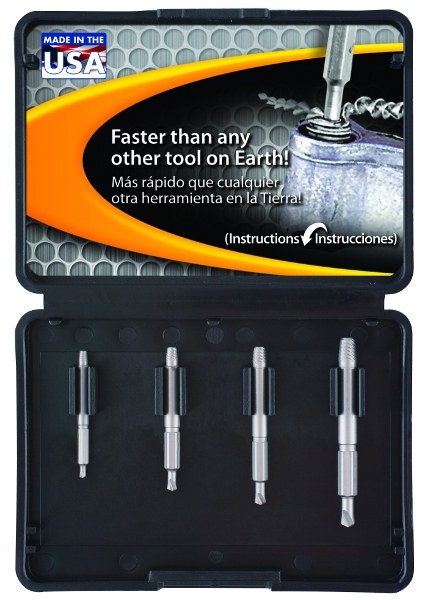

8

Simplify your life using the special tools Alden 4507P, which is designed to solve such problems as to twist a screw, a pin, a screw or the like to Unscrew the bolt. This set consists of 4 x extractors of different sizes – is a bilateral bits with a drill and taper tap to opposite ends. Insert the selected extractor drill, drill a blind hole.

9

Next, use another part of the extractor – tap. To loosen the screw with right-hand thread install left-hand rotation drills. On low speed, apply the tap-wertes in the resulting hole. Left-hand thread of the tap will create stress, contributing to the loosening stripped bolts.

Note

Protect your eyes from small chips of special glasses, the exposed areas of the body cover with clothing.

Useful advice

In order to avoid difficulties with unscrewing fasteners in assemblies operating at high temperatures, lubricate them with graphite grease. Grease and oil under such conditions may simply samokovtsa.