Instruction

1

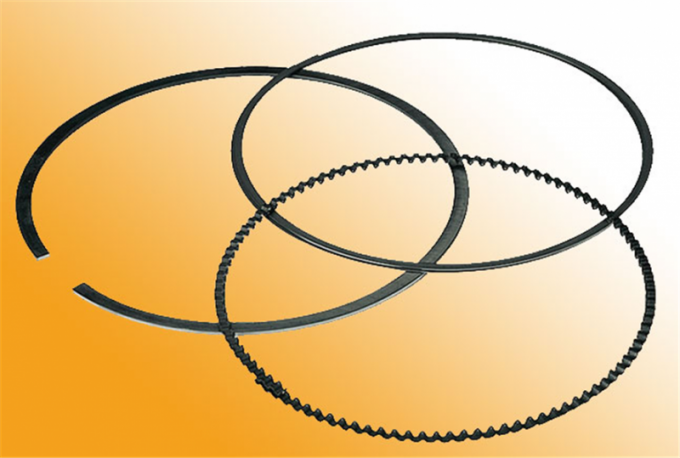

Currently, for vehicles produced piston rings of several nominal sizes, each accounting for 1-2 repair. One of the finest materials is high-strength special cast iron with high anti-wear properties. Not all domestic factories use this material, so pay attention to him in the first place.

2

Oil scraper rings are available chrome and non chrome plated. The third type is a steel ring with a spring element, choose only to install repaired motor. They are only the nominal size. Chrome rings are more suitable for engines with increased compression ratio and a more loaded mode of operation. To distinguish non chrome plated ring chrome-plated, please note the tabs. They have non chrome plated steel. And the color and those and others are the same.

3

Note the expansion of the spring. They should have the variable pitch winding of coils and polished surface on the outside diameter and end faces. Other forms of rings may either be fake, or to be made on cheap equipment and have a low resource. Check the profile and height of the protrusions. If they are absent or barely visible, then ring b/u.

4

Foreign cars are widely distributed steel oil ring due to their long service life, less weight and cost. If possible (their use is limited), get these for your domestic car.

5

When choosing the compression rings identify by touch the presence of chamfers on one or two sides of the outer diameter of the ring. Poor quality parts such chamfers are not. Another feature of high quality spare parts – bleached and rounded ends. Chrome plated compression rings creates a matte color. It will distinguish them from non chrome plated rings, with a steel luster. Using a micrometer, check the nominal and repair size ringthat is guaranteed to protect against forgery.

6

Pay attention to the marking rings. Factory label indicating the size and the firm is placed automatically in a strictly fixed place. On the forgery there are always deviations from the installed location. In addition, make sure that the rings are Packed in the original packaging in bags of 3 pieces. The packet must include: a set number, engine model and size of the rings. In the box is the number of cylindroconical-bags corresponding to the number of engine cylinders for which they are intended. All labels must be printed in one font, there should be a stamp of OTK, the point of gluing the box to be in certain places.

7

For orientation in range of piston rings use the technical documentation on repair and spare parts of the engine. There are specified the required dimensions of piston rings required for a particular repair of the power unit.

8

Setting ring small lifespan, you reduce wear of cylinder walls and longer life for the engine. But at the same time every 30-40 thousand km will have to completely disassemble the engine and change the rings. Durable rings will last 150-200 thousand km After such a mileage in both cases you will have to grind the crankshaft, and change its ear and do minor repair of cylinder-piston group. Calculate how much it will cost disassembly and Assembly of the engine every 30-40 thousand km for 200-thousand mileage and decide whether this concern about the engine of financial and labor costs.