You will need

- - brush unit with a built in integrated voltage regulator;

- - the voltmeter;

- - external voltage regulator;

- - backup generator.

Instruction

1

Modern cars generators produce three-phase alternating current which is rectified by a built-in diode bridge. In some models of generators in the brush knots are embedded integral voltage regulator. In other models, the voltage regulator is external, it is located in the engine compartment of the vehicle and connected to the brush site generator.

2

To test the operation of the voltage regulator in the car turn it the ignition system. Check with a voltmeter the voltage at the plus output relay control. It should be equal to the voltage of the vehicle battery. If there is no voltage, check supply circuit from the battery to the ignition switch, the ignition switch, the power supply circuit from the ignition switch to the relay voltage.

3

Then check the voltage coming out of relay - voltage regulator. Do it on the terminal of the brush unit of the alternator. So you check for faulty circuit from the regulator to the alternator of the car. When the vehicle engine stopped, the voltage should be equal to or greater than 8 Volts. In the absence of this voltage check circuit from alternator. If the circuit tests normal, replace the relay-voltage regulator.

4

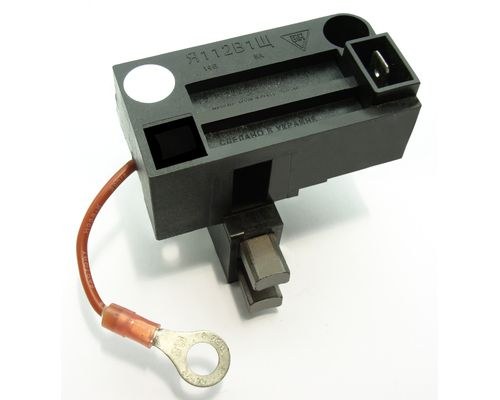

If the car is equipped with generator with built-in brush unit to its integrated voltage regulator, with the ignition on check whether voltage of 12 Volts to the terminal of the brush unit. If the voltage goes and the generator doesn't work – replace the brush unit with built-in IC voltage regulator.

5

Start the engine of the vehicle. Lift the crankshaft revolutions to 3000 rpm Measure the voltage at the plus output of the generator. It should not come out of the limit of 13.8 to 14.2 Volts. Turn the headlights on in high beam mode. Again measure the voltage at the generator output. It can be reduced, but not below a 13.3 Volts. In this case, the voltage regulator is defective.