Instruction

1

All materials capable of magnetization, divided into hard magnetic and soft magnetic. The difference between them is that the soft magnetic materials rapidly lose their magnetic properties, while the hard magnetic retain them long enough.

2

Quite a few times to hold the iron block strong magnet that he himself had magnetized. If several times to quickly open and close the iron scissors, they will begin to pull the needle or iron filings. This effect can be used if a needle fell in the narrow gap and the permanent magnet, to get it, not at hand.

3

A permanent magnet is made by magnetizing an ordinary iron, retains its properties for long. Enough to strike them on a hard surface or heat above 60 degrees so it is again demagnetized.

4

Various additives to iron, converting it into steel, can greatly change the magnetic properties. Steel capable of hardening, is a hard magnetic material and can be the basis for a strong magnet. Made of hardened steel, make files, hacksaw blade, etc. Stainless steel, used to make kitchen utensils and Cutlery, can not be either quenched or magnetization.

5

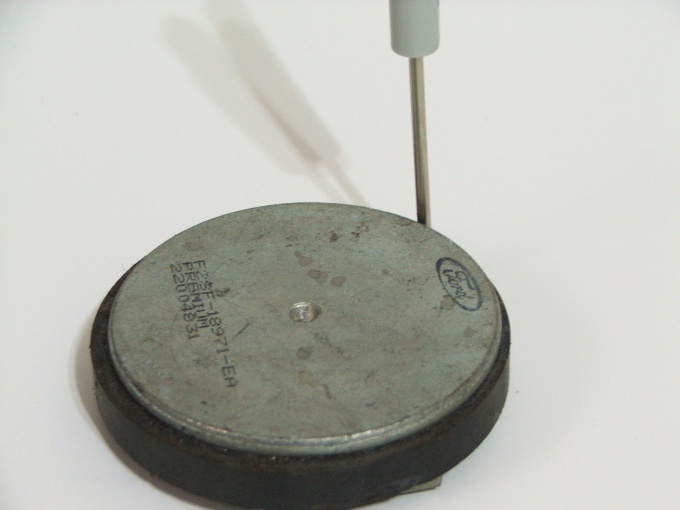

At home permanent magnet can be made of hardened steel with coil inductance. The coil should be of such size that the blank for the magnet is completely fit inside it. If you use current from the power supply, avoid short circuit, be sure to include in the diagram the fuse.

6

In addition to iron, in the industrial manufacture of permanent magnets used and other materials, for example, Alnico — alloy of aluminum, Nickel and cobalt. But the most commonly used ferrites — compressed mixture of a powder of iron oxides with various additives. Ferrite magnets on the stage of creation can be given almost any shape, they are cheap to manufacture and convenient to use.

7

The strength of a magnet is measured by instruments called magnetometers. The strongest magnets are made of sintered mixture of iron, boron and the rare element neodymium. To divide two small magnet of this material, you may want a weight of 150 pounds.

Note

If you decide to make a permanent magnet at home, strictly observe safety precautions when working with electricity. Remember that high voltage is dangerous to life, and a short-circuit may cause fire.