Instruction

1

Disassemble the device and inspect the motor. Before to remove the faulty winding, determine the number of turns. Separate the coil from the upper coil and cut. In the flame produce the firing of the coils and count the number of turns.

2

Do not remove manifold if the anchor will have to rewind manually. Inspect the manifold and check resistance of insulation relative to the housing. The resistance should not be less than 200 kω. Clean the header from the remnants of the old winding and cut the slots in the contact parts of the collector, and then to insert the ends of the rails for sealing.

3

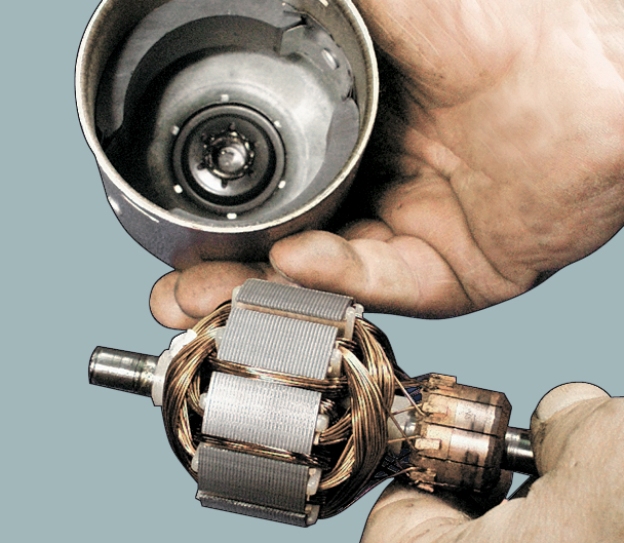

Cleaned the anchor sugilite. Fabricate casings of electrical cardboard with a thickness of 0.2 mm and insert them in the slots of the armature. After you install the updated manifold, cleaning the armature and inserting it in the grooves of the sleeves start winding coils.

4

During circular winding down the turns of the coil successively to fill all the slots of the armature. Styling produce counterclockwise when viewed from the side of the shaft, such laying is called laying to the right.

5

Don't forget to apply a bandage to the coil in the center of the manifold to secure the turns of the coils. The bandage consists of several coils of their thick strands which should be wound tight and tie. Do not use a filament of nylon – it may melt during operation of the armature. The best variant – cotton thread.

6

Check the device for the absence of interturn short circuits and breakages of the winding. It must be done prior to treatment, since untreated anchor the faulty winding is easy to see.

7

To secure the turns of the coil produce impregnation. It can be made of epoxy for heat curing with a plasticizer. In the impregnation at home you can also use any nail Polish.

8

In the end, make the groove. It will depend on the degree of sparking. Runout should not exceed 0,05 mm. the Cutter must be properly sharpened for brass. At the end of the groove, make the second check for the absence of interturn short circuits.