You will need

- cable;

- portable male to HDMI;

- - soldering iron.

Instruction

1

As a rule, usually needed to make the HDMI cable does not occur as in the market you can find good quality samples worth several dollars. You should know that the difference in quality of signal transfer from the cable and the cost of several hundred dollars no. The signal is in digital form, so it comes without any distortion. As the person who purchased the instrument is high definition, hardly stinted on the cable at a cost of 5-10 dollars, we can only talk about some special situation. For example, the required cord is a great length, which you have to solder yourself.

2

In the process of producing cable you will need a split plug HDMI. So how to find this problematic, there is another option – to buy a collapsible plug to DVI, and it to take the HDMI adapter. You will also need a quality cable - twisted pair 8-th or 7-th category.

3

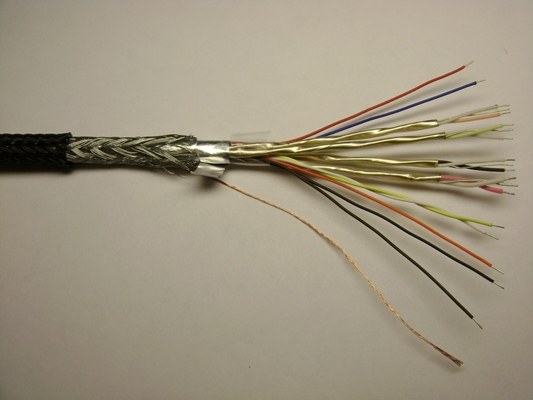

The exact scheme for DVI and HDMI connectors look at the websites referenced at the end of the article. You will need a miniature soldering iron up to 25W. As the wires are quite thin, it is necessary to work very carefully. To obtain high quality connections and warning circuits should be used heat-shrink insulating tube. Short cut tube slip on the wire, then solder it. Slide the heat shrink on contact and warm. Compressed insulation tube connection will be very reliable.

4

If you have to solder a few pieces of cable, it is important to connect not just wires and screens. With poor shielding in the transmitted signal may cause interference, which is manifested in the appearance of the screen sections of crumbling squares of the image.

5

Sometimes a situation may arise when the cable because the plug cannot be pushed into the hole in the wall, baseboard, furniture etc. So as not to drill the wall and not to spoil the furniture, it is easiest to cut the cable, push it into the hole, then carefully solder all the wires. It's easier than, for example, to remove the plug and then replace it with the new collapsible. Before cutting the cable, cut first on a small area of the insulation and mark all the cores, so you do not confuse them when connecting.