Instruction

1

Make fuel mixture, chuckle nitrate, charcoal and sulfur in the correct proportions to Make a mixture of the wick by mixing saltpeter and sulfur at the rate of 9 parts nitrate to 1 part of sulfur.

2

Drill out the metal part of the casings from the fixing capsule. Remove the fasteners capsule.

3

In the Board hammer the nail in. The nail should protrude 2 cm above the Board. Raised Knez nail gently grind, giving it a smooth tapered contours. The sharp end is slightly blunted.

4

Carefully remove any metal filings. Put the sleeve the metal part on the nail and cover it well-mixed fuel at ¾ height.

Using a wooden round stick extrude the fuel in the sleeve, lightly hitting it with a mallet.

Using a wooden round stick extrude the fuel in the sleeve, lightly hitting it with a mallet.

5

Cut out writing paper circle slightly larger internal diameter of the sleeve. It needs to completely close the fuel layer. On top of the resulting partitions pour fuel mixture with a layer of 0.5 cm and seal the liner top layer of thin paper. This charge is for the discharge chute.

6

Take a round stick of larger diameter. Wrap it with a layer of newsprint. Secure with glue and let dry. Then lightly soak the newspaper layer of oil and wipe off.

7

Wrap the resulting preform is a tube of drawing paper 2-spiral thick. Carefully RUB each round with glue. Dry the tube on the stick.

Remove the tube from the stick. Remove the layer of newsprint, it is no longer needed.

Remove the tube from the stick. Remove the layer of newsprint, it is no longer needed.

8

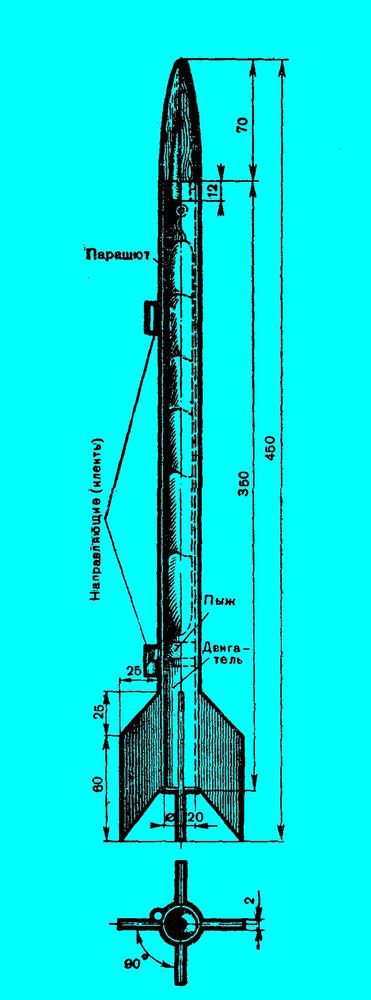

From the soft wood, make the cone of the rocket. It is a tube with a length of 6-7 cm, the upper end of which falls on the taper and rounded ends, and the bottom 1-1. 5 cm is inserted firmly into the upper part of the paper tube. You poluchili the body of the rocket and fairing.

9

Make of paper stabilizers. There should be at least three. They represent the triangles and must have a soul connection with a rocket. Stabilizers to the body of the rocket fasten with glue. From the end of the cone that is inserted in the body of the rocket, fasten a metal ring or bracket inner diameter of 0.5 cm, made of steel wire. Close the jump ring. It serves to attach the parachute.

10

Insert the core-the engine in the lower part of the rocket. It must be tightly and go back to the requirement. If the engine is poorly kept, from the inside: glue the extra paper ring is 3 cm wide and Completely dry the hull. Paint it with waterproof paint in a bright color.

11

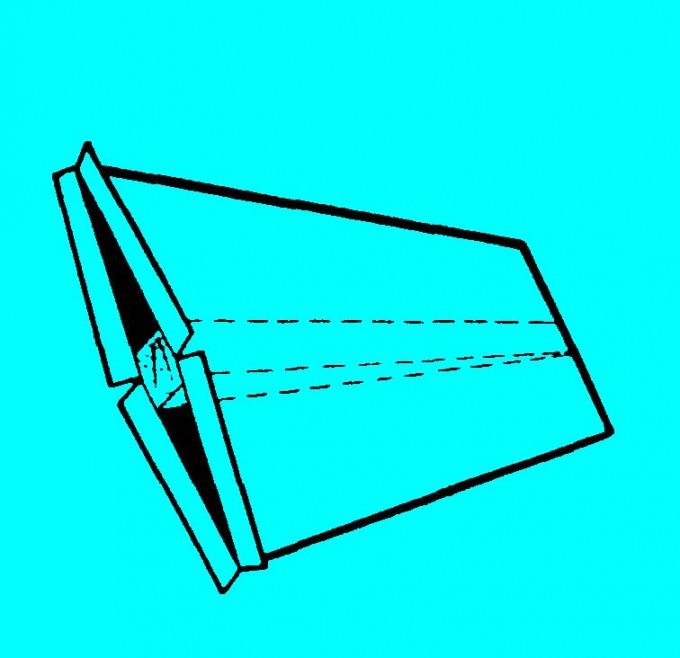

Make a parachute. The diameter of the dome of 15-20 cm For this model to apply tape chute. One end of the ribbon attach to a wooden stick. To the ends of the sticks, attach the loop of string with a length of 10 cm To one end of the loop tie a piece of aviation rubber with a length of 10 cm. the End of rubber thread and tie around the wire ring, to put on the fairing. Additionally secure it using a normal thread. The ring fairing tie another thread a length of 10 cm also tie a piece of aircraft tires, but it still is 5 cm normal thread. Fasten the thread on the inner side of the rocket body in three inches from the upper end of the tube body. You can skip through the entire body, making a hole in it and paste over for the strength of the paper ring.

12

Lay the parachute. To do this, wind the tape into a roll, starting from the free side. Press the coil with the wand, which is attached parachute. Gently slide the resulting coil in the body of the rocket. Lay on top of ribbon and thread mounting to the fairing. Close the design of the fairing.

13

Make a starter device. Cut a piece of iron wire of length 120 cm of paper on the wire glue 2 of a cylinder 1 cm long and with a diameter slightly larger than the diameter of the wire. The ring should slide freely on the wire. Received ring clip on one of the longitudinal lines on the body of the rocket durable glue. One ring hook at the junction of the housing with the stabilizer, and the other in the upper part about 1 cm from the fairing. The rocket should slide freely on the wire. At a distance of 50 cm from one end of the wire wrap it restrictive ring from any wire. The way please this ring the rocket to fall should not be. This side of the wire to stick into the ground.

14

Make the fuse. You can get a fuse from firecrackers or fireworks, but the length may be insufficient. Make stopin. Take the cotton thread and fold it 6 times. Supposed to be a segment of length 8 cm. Cook the paste. Moisten the thread of the starch paste. Dip its whole length in a composition similar to fuel, but no coal. The threads should stick a layer of the composition. The cord dry.

15

Before you start, insert the engine into the rocket. Before to paste it in the body of the rocket, insert the wad. Wad can be a piece of foam. Bend the cord at one end and insert this end into the nozzle. The rocket is ready