You will need

- calculator;

- - dynamometer;

- - the range.

Instruction

1

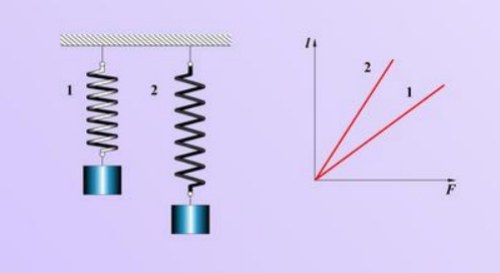

Attach to the body of the load cell and pull it, deforming the body. Power that will show the dynamometer, will be modulo equal to the force of elasticity, acting on the body. Find the coefficient using Hooke's law, which says that the force of elasticity is directly proportional to its elongation and directed in the direction opposite to deformation. Calculate the stiffness coefficient by dividing the value of the force F on the extension of the x body, which is measure with a ruler or tape measure k=F/x. To find the elongation of the deformed body, subtract the length of the body is deformed from its original length. The stiffness is measured in N/m.

2

If there is no dynamometer, hang to deformable body cargo known mass. Make sure that the body is elastically deformed and not destroyed. In this case, the weight of the load will be equal to the elastic force acting on the body, the coefficient for which you want to find, for example, springs. Calculate the stiffness coefficient by dividing the product of the mass m and the gravitational acceleration g≈9.81 m/S2 on the elongation of the body x, k=m•g/x. The elongation measure by the method proposed in the previous paragraph.

3

Example. Under the weight of 3 kg and a spring of length 20 cm was 26 cm, determine its stiffness. First, find the elongation of the spring in meters. To do this, the length of the elongated springs, subtract its length in normal condition x=26-20=6 cm=0.06 and m. Calculate the stiffness using the formula k=m•g/x=3•9,81/0,06≈500 N/m.

4

In the case where the known potential energy elastically deformed body, calculate its rigidity. For this additional measure its elongation. Stiffness will be equal to the doubled potential energy EP divided by the square of the elongation of the body x, k=2•Ep/x2. For example, if a ball is deformed by 2 cm and a potential energy of 4 j, then the stiffness k=2•4/0,022=20000 N/m.