Instruction

1

Limit strength is based on the theory that any material able indefinitely to withstand a static load of any power, if it forms a voltage quantity which does not exceed the tensile strength. If the title is resistance, which is equal to the temporary voltage, the destruction of the prototype will happen in an undefined finite time interval.

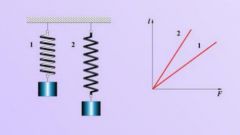

2

For measuring limit strength also apply the concepts of yield, proportionality, endurance, etc. the value of the temporary fracture resistance in tension of the material and its compression for different substances vary significantly. For brittle materials, which include ceramics, limit strength in compression is greater than its value in tension, for composite materials characterized by the opposite situation, and plastics and metals usually show the same limit of strength in both directions.

3

To calculate the limit of strength, it is necessary to know the force that occurs in the body during the deformation of the object, and the exposure area on the subject of outside forces. Mechanical stress at a point is equal to the ratio of internal force in Newtons per unit area at a particular point of cross section in m2. I.e. the external influence aimed at changing the position of particles relative to each other, and the tension that occurs in a substance at the same time, prevents this change in location and limit its spread. Distinguish normal and tangential stress, which differ in the direction of application of force.

4

In the formula σB is expressed as Q = FS, where S is the surface area, and F is the force deformation, resulting in the body.The maximum possible number of mechanical stresses for a particular substance and is the limit of his strength. So the limit for steel is 24000 MPa, and the yield stress for nylon - 500 MPa.