You will need

- - copper wire of the desired diameter;

- technical gloves;

- - pliers;

- - a means for washing dishes;

- - impregnating varnish.

Instruction

1

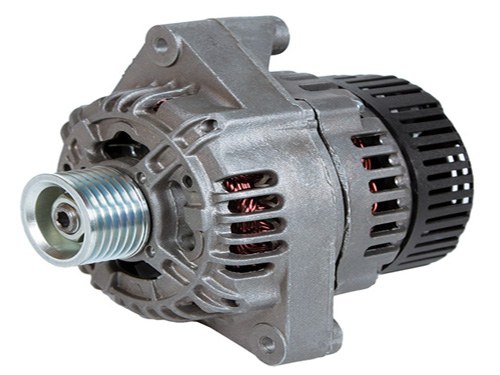

The component parts of the generator AC are the stator and rotor. The stator is the stationary part of the generator, consisting of a header and multiple windings. The collector is designed to relieve stress, which occurs in the windings of the rotor, and for subsequently feeding it into the circuit of consumption. The movable part of the generator is called a rotor consisting of a certain number of magnets, on which is wound a coil made of copper wire.

2

Speaking purely theoretically, in order to increase the capacity VAZ, you need to replace the rotor winding, while using a drive larger cross-section and increasing the biasing current.

3

In practice, you first need to draw a diagram of the winding of the rotor coils, then unwinding them. To do this, take a copper wire of the required diameter, technical gloves, pliers, and please be a bit patient.

4

Remember, the wire you unwound, has been specially impregnated with varnish. So be sure to wash and degrease the rotor coil. For this purpose resort to the use of pre-prepared regular household dishwashing detergent.

5

Take the prepared copper wire, then very carefully, slowly, to wrap his turn to turn on the coil. Don't forget to record the number of turns. When the winding is finished, strip the ends of wires and test them with tester to "short circuit".

6

Now you must carefully sealed all the exits, and then solder them to the contacts. Impregnated with a special varnish all the winding, then drain. Solder wire for the connection.

Note

When you draw a diagram of the winding of the rotor coils, be sure to unwind them. It is also essential to record all the number of turns. Mandatory record their location and lock the circuit outputs.

Useful advice

Spooling wire, remember that in order for it to lay down nice and straight, it is necessary to pull. The process is fairly tedious, nonetheless, is required!