You will need

- pipe Ø 100 mm;

- corner 100x100 mm;

- - angle grinder ("grinder");

- - welding machine;

- - cement;

- - sand;

- - edged Board and timber for formwork;

- - a carpenter's tool;

- - shovels and spade shovels.

Instruction

1

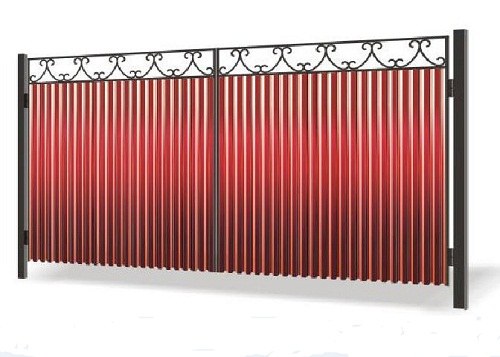

Cut blanks for the gates. Use stands for pipe Ø 100 mm or area of 100x100 mm. Their length is determined by the amount of gate height and length of the ends, sealed in the ground (0,8-1 m). When the planned height of the gate 2 m length of the blanks should be equal to 2.8 to 3 m.

The bridge between the racks, make area of 100x100 mm. Its length should be equal to the width of the gate. For standard gates, it is taken equal to 3 m. If the quality of the rack pipe is used, cut one shelf area on both sides at an angle of 30° and give the edge a concave shape. This is to ensure that the edges of area well close to the stands when they are welded.

The bridge between the racks, make area of 100x100 mm. Its length should be equal to the width of the gate. For standard gates, it is taken equal to 3 m. If the quality of the rack pipe is used, cut one shelf area on both sides at an angle of 30° and give the edge a concave shape. This is to ensure that the edges of area well close to the stands when they are welded.

2

Collect the pieces of the woodwork on the ground, choosing for this place flatter. It should be similar to the letter "N" – two posts and a lintel laid between them at a distance of 2 m from their top (or 0.8-1 m from the bottom). This should be provided two conditions: the parallelism of the racks between themselves and perpendicular alignment of the jumper towards the racks.

3

Weld the crosspiece to the posts. Both shelves parts must be securely welded by a continuous seam. Weld to the web in two or three places any pieces of metal, sending them down. They will play the role of rebar, firmly connecting the jumper with the Foundation.

4

Dig a trench for the Foundation pouring. Its width should be 350 to 400 mm, length – 3.5 meters (3 meter gate). The depth of the trench is determined based on the depth of freezing of the soil type, groundwater level. For simplicity, we can take it equal to the depth of soil freezing in your area, which can be found on construction sites.

5

Fabricate wooden boards edged boards and assemble them from the formwork. Its dimensions must be 0,3x3,3 m. Wall formwork it is advisable to do a little widening towards the bottom to avoid the buoyancy effects of the soil on the Foundation.

6

Install gates in the formwork so that the jumper was on the same level with the ground surface and stands vertically. To do this, put the racks or jumper struts made of stones or metal, and fasten the stand with two stops. Put into the formwork rebar from any kind of metal – wire scraps, metal profile, etc.

7

Prepare a sand-cement mortar ratio 1:4 (cement:sand) and pour it into the formwork. To spend less solution, fill the formwork with stones and broken bricks. During Drambuie fill the mortar with a shovel. The surface of the cast Foundation should be at the same level with the ground and a jumper. Before to hang the gates themselves give the solution time to harden – at least a week.