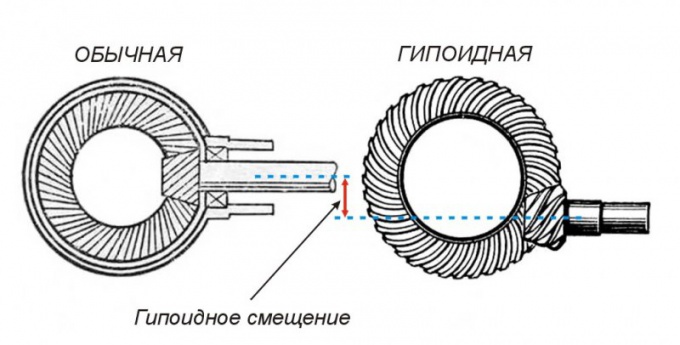

Hypoid gear (gear) transmission is different from the ordinary, with straight or oblique teeth, the teeth are curved. They are bent in a special geometric curve of the hyperboloid, which can be seen in the figure. Hence the name: hypoid – short for hyperboloid.

The main features of the hypoid transmission have two. First, it can be applied only at nodes with intersecting axes of subcateg. Try to build a hypoid gear transmission with parallel shafts makes no sense: it immediately jammed.

Second, the axle shafts must be offset from each other, otherwise, again jamming. The amount of offset must be an exact match with the mathematical parameters hypoid, the so-called hypoid offset.

For the first time in automotive hypoid main gear applied engineers of the American firm Packard in 1926 What is the result?

First, the driveshaft dropped down the amount of hypoid offset. It is possible to reduce the height of the tunnel in the cabin and to lower the center of gravity of the machine, thereby improving its stability.

Second, torque of the hypoid gear transmits more smoothly than helical, not to mention spur. Finally, a hypoid gear is less noisy and can transmit more torque than normal. As engineers say, it has a large load capacity.

All this, taken together, increases as the car comfort and its durability. Therefore, hypoid main gear – an indispensable attribute of cars is quite high class, such as Lexus infinity.

However, hypoid transmission has significant drawbacks, besides the complexity of manufacturing and, consequently, cost. During rotation of the gears occurs due to the fact that the teeth are curved, the force acting along the axis of the small pinion gear. As a result, the hypoid gear is very sensitive to wear, workmanship is not only of gears but also of all its parts, especially bearings. When it is inaccurate adjust it easily jammed, especially when changing the direction of rotation when reversing.

Teeth hypoid transmission are adjacent to each other tighter than usual, so she is also very afraid of contaminants in the oil. The oil in the crankcase hypoid gear you should fill only special hypoid, anti-wear and extreme pressure additives. And pour to a certain amount.

However, all the shortcomings of the "hypoid" far outweighed its benefits, and technologically they are quite surmountable. With the development of the automotive industry and the General culture of production "hypoid" passed in the transmission of consumer class machines. Now it can already be seen in the budget Chinese cars.

The main features of the hypoid transmission have two. First, it can be applied only at nodes with intersecting axes of subcateg. Try to build a hypoid gear transmission with parallel shafts makes no sense: it immediately jammed.

Second, the axle shafts must be offset from each other, otherwise, again jamming. The amount of offset must be an exact match with the mathematical parameters hypoid, the so-called hypoid offset.

Advantages of hypoid transmission

For the first time in automotive hypoid main gear applied engineers of the American firm Packard in 1926 What is the result?

Main gear transmits torque from the propeller shaft to the differential wheels. Is always downshift to match the engine speed with the required wheels, and to increase the stall torque on them.

First, the driveshaft dropped down the amount of hypoid offset. It is possible to reduce the height of the tunnel in the cabin and to lower the center of gravity of the machine, thereby improving its stability.

Second, torque of the hypoid gear transmits more smoothly than helical, not to mention spur. Finally, a hypoid gear is less noisy and can transmit more torque than normal. As engineers say, it has a large load capacity.

All this, taken together, increases as the car comfort and its durability. Therefore, hypoid main gear – an indispensable attribute of cars is quite high class, such as Lexus infinity.

Its shortcomings

However, hypoid transmission has significant drawbacks, besides the complexity of manufacturing and, consequently, cost. During rotation of the gears occurs due to the fact that the teeth are curved, the force acting along the axis of the small pinion gear. As a result, the hypoid gear is very sensitive to wear, workmanship is not only of gears but also of all its parts, especially bearings. When it is inaccurate adjust it easily jammed, especially when changing the direction of rotation when reversing.

There is a silver lining: the tendency hypoid transmission to jamming is used in the center (the center) limited slip differential type Torsen. They are used in vehicles with full automatic drive (4WD).

Teeth hypoid transmission are adjacent to each other tighter than usual, so she is also very afraid of contaminants in the oil. The oil in the crankcase hypoid gear you should fill only special hypoid, anti-wear and extreme pressure additives. And pour to a certain amount.

The use of hypoid transmission currently

However, all the shortcomings of the "hypoid" far outweighed its benefits, and technologically they are quite surmountable. With the development of the automotive industry and the General culture of production "hypoid" passed in the transmission of consumer class machines. Now it can already be seen in the budget Chinese cars.