Aluminium metal is light silver color. It is lightweight, relatively soft, melts at a temperature of — 660,4°C. Al is readily soluble in strong alkalis, resistant to acids, since on its surface a protective film is formed. Finely divided metal when heated, burns in air. The smaller the particles, the lower the temperature needed for ignition.

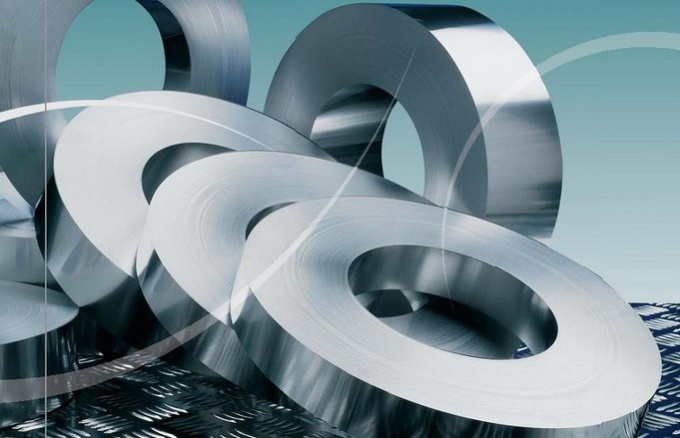

Aluminium has high thermal and electrical conductivity. This metal is very plastic. This property allows you to roll it into very thin foil. He also has low strength: pure aluminum can be easily cut with a knife. This metal is very resistant to corrosion - on the surface of Al is formed a thin film that protects it from destruction.

Depending on the amount of impurities - purity metal in accordance with GOST, aluminum is assigned a specific brand.

Made of anodized aluminum was obtained in 1909 in the town of Duren, Germany. New chemical alloy which was named in honor of the city, quickly gained popularity on the planet. The approximate composition of duralumin: 94% aluminium, 4% copper, 0.5% manganese, magnesium, iron and silicon. The alloy is heated to 500°C, then quenched in water and subjected to natural or artificial aging.

Duralumin after quenching acquires a special hardness and becomes about seven times stronger than pure aluminum. He, however, remains light - almost three times lighter than iron. The alloy was much stronger, but lost one of the most important properties — corrosion resistance. Again had to use aluminium for corrosion control. Items made from duralumin, began to planirovat, i.e. to cover a thin layer of pure aluminum.

In everyday life, so-called food aluminum. According to GOST food aluminum must contain a very small amount of impurities of lead, zinc and beryllium. It is also resistant to corrosion because its surface forms a dense oxide film. Aluminium for domestic purposes is used very widely. From it are made spoons, forks, pans, basins and other utensils. Tubes produce toothpaste, sauces, condiments, canned food.

Why is food so often used aluminium for the food industry? This metal is not prone to corrosion, so the Cutlery and kitchenware can last a long time interaction with water. When storing products in contact with this metal, the smells and tastes remain unaltered, and the vitamins in the cooking process are not destroyed. Aluminium is a good conductor of heat, thereby accelerating the cooking process. This metal has sufficient rigidity - it is not deformed in the cooking process. In addition, it can be used in ovens and microwave ovens. Aluminium food is absolutely harmless to health material.

Food foil also found very wide application. But the foil is a thin rolled aluminium thickness 0.009 mm to 0.2 mm. Is an excellent packaging material. In the confectionery industry it is wrapped cookies, candy and ice cream. Wrap foil used for packaging butter and margarine.

The obtained food packaging has become popular not only because of its strength and flexibility. Aluminum foil is very resistant to external influences: external odors, high humidity. It does not interact neither with the food nor with her scent, that is not cheating them.

Aluminium has high thermal and electrical conductivity. This metal is very plastic. This property allows you to roll it into very thin foil. He also has low strength: pure aluminum can be easily cut with a knife. This metal is very resistant to corrosion - on the surface of Al is formed a thin film that protects it from destruction.

Depending on the amount of impurities - purity metal in accordance with GOST, aluminum is assigned a specific brand.

Duralumin – aluminum alloy

Made of anodized aluminum was obtained in 1909 in the town of Duren, Germany. New chemical alloy which was named in honor of the city, quickly gained popularity on the planet. The approximate composition of duralumin: 94% aluminium, 4% copper, 0.5% manganese, magnesium, iron and silicon. The alloy is heated to 500°C, then quenched in water and subjected to natural or artificial aging.

The most common alloy of aluminum today is made of anodized aluminum.

Duralumin after quenching acquires a special hardness and becomes about seven times stronger than pure aluminum. He, however, remains light - almost three times lighter than iron. The alloy was much stronger, but lost one of the most important properties — corrosion resistance. Again had to use aluminium for corrosion control. Items made from duralumin, began to planirovat, i.e. to cover a thin layer of pure aluminum.

Aluminium in everyday life

In everyday life, so-called food aluminum. According to GOST food aluminum must contain a very small amount of impurities of lead, zinc and beryllium. It is also resistant to corrosion because its surface forms a dense oxide film. Aluminium for domestic purposes is used very widely. From it are made spoons, forks, pans, basins and other utensils. Tubes produce toothpaste, sauces, condiments, canned food.

Why is food so often used aluminium for the food industry? This metal is not prone to corrosion, so the Cutlery and kitchenware can last a long time interaction with water. When storing products in contact with this metal, the smells and tastes remain unaltered, and the vitamins in the cooking process are not destroyed. Aluminium is a good conductor of heat, thereby accelerating the cooking process. This metal has sufficient rigidity - it is not deformed in the cooking process. In addition, it can be used in ovens and microwave ovens. Aluminium food is absolutely harmless to health material.

Food foil also found very wide application. But the foil is a thin rolled aluminium thickness 0.009 mm to 0.2 mm. Is an excellent packaging material. In the confectionery industry it is wrapped cookies, candy and ice cream. Wrap foil used for packaging butter and margarine.

Due to their ability to conserve heat, the foil is used for the storage and transportation of products. And in the process of bending and folding the integrity of the foil is not broken.

The obtained food packaging has become popular not only because of its strength and flexibility. Aluminum foil is very resistant to external influences: external odors, high humidity. It does not interact neither with the food nor with her scent, that is not cheating them.