You will need

- - grinding wheel;

- - protective glasses or a protective shield;

- - special templates or tool protractors;

- - magnifier that increases 10-20 times.

Instruction

1

Getting to the sharpening of the cutter, install on the machine the grinding wheel. Make sure it is securely protected with safety cover. If you are going to grind lathe cutter HSS, use a medium hardness grinding wheel of electrocorundum with grain size 40-20. And sharpening cutting tools made of hard alloy spend on another grinding wheel - green silicon carbide.

2

Pay attention to the surface of the grinding wheel. It should be smooth, not visibley. Otherwise, the grinding wheel is subject to revision. The edit is artificial diamond substitutes diamonds, and special cutters.

3

For protection of eyes from the ingress of metal or abrasive dust be sure to wear safety glasses. For these purposes it is possible to use a protective visor.

4

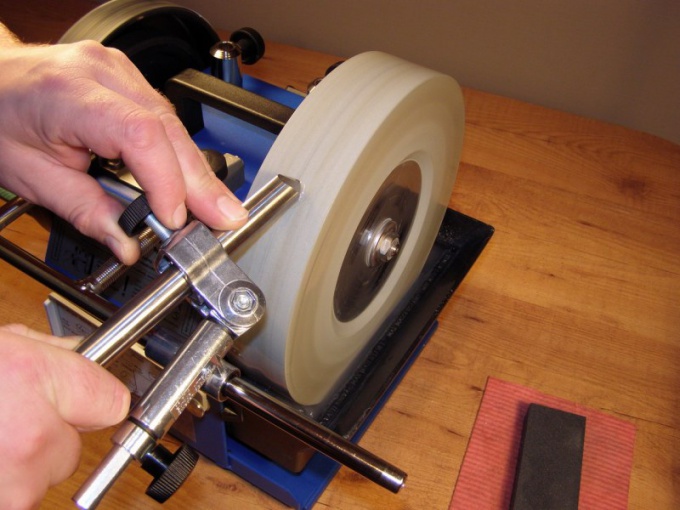

Not to keep turning the cutter on the weight, set it on the armrest. And the armrest appropriately position the grinding circle under a certain angle, closer to him. So you are in the process of sharpening of the cutter will provide a reliable support.

5

Start sharpening the cutter with the main rear surface, then go to the main auxiliary, and in addition treat the front surface of the tool. Then zakruglenie the top of the cutter.For uniform wear of electrocorundum or silicon carbide sharpening move the tool along the surface of the circle. To avoid overheating, do not strongly press down the cutter to the circle. Otherwise, the cutter can cause cracks.

6

Getting to the sharpening of the cutter, secure it an abundant continuous water cooling. Otherwise, better to use dry sharpening. In the sharpening process do not use drip cooling or dip cutter in water.

7

Check the angles of sharpening the cutter using the template. The rear surface of the cutter to press the side surface of the template. Lack of clearance will indicate on the right rear corner. The angle of taper test cut of the template. Also you can check the sharpening angles with a special tool theodolites.

8

After checking the angles of sharpening, inspect the resulting quality of the cutting edge. For this you will need a magnifier having a 10-20 fold increase. Make sure that the cutting edge sharp without rounding, scratches and cracks. When such defects have a cutter reground.