Instruction

1

Calculate characteristics and the number of turns of the future step-down transformer. To do this, find out the voltage in the primary network, the voltage you want to output, and the cross-sectional area of the core. So, if you are planning out voltage 220 B to 12 B in cross-sectional area of 6 sq cm, then you need a constant value for the average transformer iron, which equals 60, divided by the area. Get that for each Volt represents 10 turns. Multiply this by 220 and the result is the number of turns of the primary winding. The secondary winding is calculated as: 10 turns multiply by 12 Volts.

2

Take the lead, which is present in silk or cotton insulation. Section select small, about 0.3 mm. To locate the secondary winding wire cross-section 1 mm. Stock up on tinplates for the manufacture of the core. To do this, take the cans and cut them about 80 strips of width 2 cm and length of 27-30 cm Otoshita them in the oven and allow to cool, then clean off the scale, cover them with varnish and paste over one side of thin paper.

3

Make the frame for the coil. It can be made from thick cardboard. Pre-wrap it in several layers of paper preparativnoi. Then start winding the wire. Ensure that after two or three rows of laid paper. The ends of the primary winding clip to the frame and lay several more rows preparational paper.

4

The secondary winding route in the same direction as the primary. Don't forget the insights you need to make 120 and 240 turns (by calculation). Insert the iron strips in the finished coil that should be half its length. They go around the frame with one hand and connect at the bottom. Leave between the core and the frame of the air gap.

5

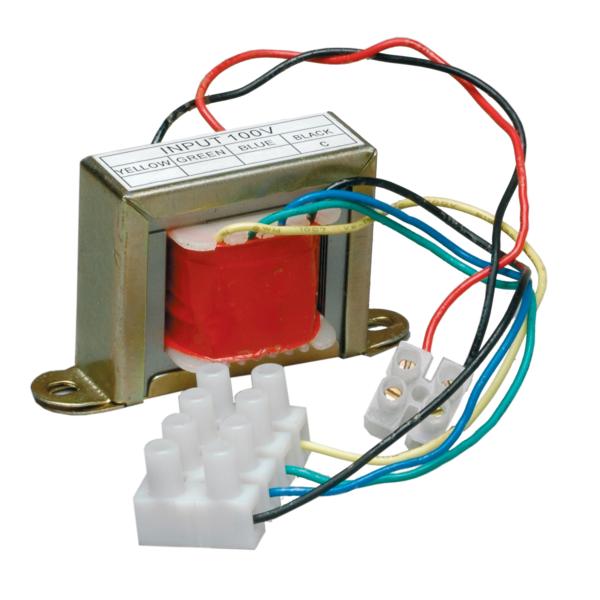

Make the base of the transformer. To do this, take a small Board with a thickness of about 5 cm, fasten with metal braces that wrap around the lower part of the core. Print on the frame the ends of the windings and secure them to the contacts.