You will need

- a specialized set of tools;

- - knife-cutter;

- - pliers (preferably ceramic).

Instruction

1

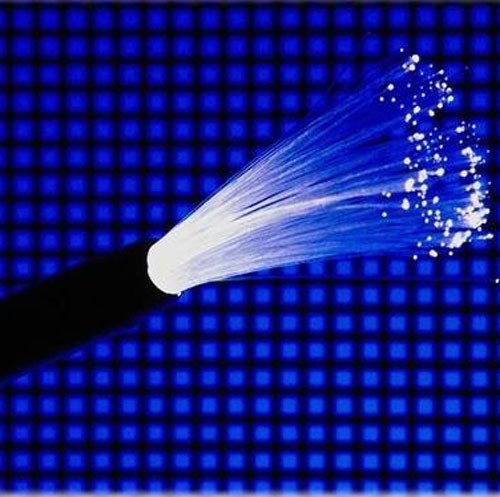

Swage fiber starts with cutting the cable. Removing the top layer of his armor and almost no different from working with copper counterpart. One thing to remember is not to avoid kinks and severe bends of the cable, because the fiber is very fragile in its structure.

2

After removing the first of two protective sheets, it is necessary to work with more accuracy so as not to damage fiber core. Try cutter to make a shallow longitudinal incision, without violating the integrity of the plastic braid. Now remove the plastic covering and unwind the protective tape.

3

The next stage of work can only be performed using a specialized set of tools. Buying such a kit is not cheap, because the ultimate result usually depends on the quality of the tools.

4

Next, you need to remove the buffer coating. Now to work necessarily through of a stripper. Installing the minimum diameter (usually there are only three possible) carefully incise the buffer coating. Then gently push it with fiber, avoiding kinks.

5

Now you must go to the Assembly connector. Thread the fiber into the hole of the tip and lock it there using a particular glue included in your kit. After hardening of the adhesive mass is necessary to remove the excess fiber. To do this, with the help of Scriber to the fiber should be applied first notch, and then chipped it. Further, using a set of sandpaper you should clean the tip. Go from larger to finer sandpaper, thereby first improving and then polishing and bringing fiber to the required quality.

6

To check your work, you need a special light microscope. In the case where the edge of the fiberglass you will see a bump or chip, you must either modify the tip sandpaper or re-trim mine and to begin work on a new one.

Useful advice

It is worth noting that working with fiber in all its stages requires enough experience and patience and specialized tools. So if you have any desire to build to your office or home optics, it is best to consult a specialist.