Instruction

1

Take drop-in anchors with internal thread LA, LAH. This type is the simplest. It is used for the installation of stone, brick or concrete structures. Assembly is performed in a pre-drilled hole of the required diameter and depth. It clean - this must be done for any type of anchor. Install into the hole and screw it. Reliable degree of fixation is achieved by unclamping the fastener. The same type multifunction anchor MTA, which is used for bases having internal cavities.

2

Take a wedge anchor, which is produced by hot-galvanized, acid-resistant and zinc plated. It is equipped with a special wedge, extending in the installation process and fixed in the nest. Enables end-to-end installation through installed on the base material. Place it in the prepared hole, then hammer a hammer and tighten with a wrench. To similar type fasteners applies a screw anchor. They are equipped with a screw with countersunk head head. This gives the opportunity to use them when mounting door and window frames. The wedge anchor is securely fixed in design as you tighten the screw.

3

Install the rod retainer. It operates on the principle of the V-anchor, is designed for deep installation through several consecutive layers of insulation and cladding. An additional advantage of this product is the ability to set it at an angle. Such a rod clamping mechanism in the socket with the help of the expanding wedge is used in the anchor TA. The part with internal thread together with the rod which can be cut if necessary to desired length, used for mounting several layers of material. Hammer the anchor into the prepared hole, fix the fixable material on the rod with a washer and nut.

4

Install the anchor PFG with screwing. It has an internal thread, and in the process of installation, the plug-in elements are extended and firmly fixed in the nest. This product can be used in combination with inserted conical bolt, bolt with loop and hook-shaped head or with inserted liners. PFG anchor is used for solid grounds.

5

Install brass anchor MSA by screwing. Suitable for use in a brick or concrete Foundation. Its the brass sleeve has an internal cavity of conical shape (with thread), tapering to the tip. As you tighten the screw it is distributed in width and securely pressed against its rough walls to the inside of the holes in the base.

6

Take for gypsum panels anchor DRIVA. It is made in 2 versions: nylon and zinc alloy with aluminium. A metal option is suitable for particleboard. Screw his power tool right into the base, therefore he does not need pre-drilling. Then install and fasten the material and screw in the anchor screw.

7

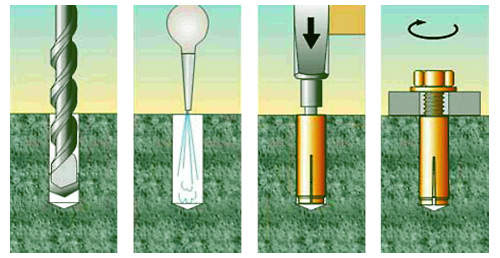

Install the anchor bolt, which is considered one of the most reliable in the mounting construction of the tools. This specific type of fasteners, which cannot be substituted by neither plug nor the usual nail. Usually anchor bolt attaches the equipment that connects the building constructions and concreted, sometimes laid brickwork. It is used in various fields - mount pendant fixtures and ceilings, doors and Windows, and when vertical installation. Method of installation: drill a hole with a diameter that matches its outside diameter. Clean the hole from dust and insert the anchor bolt, with a little raskladov the sleeve. Installation is considered ideal when it is embedded in a level concrete or flush. Setting the anchor in the concrete, tighten bolt head.