You will need

- the tape measure and calipers.

Instruction

1

Define expected mode of operation of the construction within which you intend to use the dowels. For use of the design inside the room there is a fundamental difference in the materials used for the production of dowels – the main materials today are nylon and polypropylene. All external construction, the operation of which will be held in more severe weather conditions require a more responsible approach to the material, so for outdoor use it is better to apply anchors of more resistant to external temperature influences, the polyamide nylon.

2

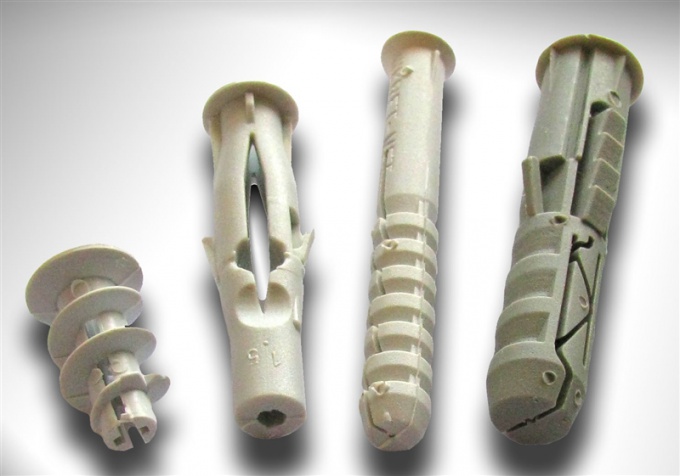

Determine the type of the surface, which will have to bury the dowel. For solid walls using spacers or activity dowels; to hollow, hollow or laminated wall suitable anchor dowels. In addition, there are also a number of anchors for special purposes. It anchors for drywall, sheet metal, surfaces, façade and others.

3

Determine the degree of the load, which will test the design in place of hardware - this will depend on the type and thickness of the dowel and also the magnitude of its penetration in the wall or structure. The General rule is that the more the load will be to use a fixing unit, the deeper must be fit and more powerful himself dowel. Typically, create hard mount using dowels with a diameter of 8-10 mm, and bury them in 30-100 mm depending on the thickness and heaviness of the attached design. The most responsible are considered a fastener in which the load acts on the dowel vertically or horizontally on a break. In that case, when the load on the dowel acts vertically downwards, it is also important to take into account the device itself plugs – push-in dowel should contain a special external notches, reinforcing the grip and the spacer antennae or wings.

4

Drill a hole under the concrete plug. This is done so that the dowel can be driven into the hole with some force. Typically, the diameter equal to the diameter of the drill hole or is slightly smaller. For greater strength of attachment of the dowel in the hole you can use a glue such as PVA, after brushing them with the dowel. In this case, use the screws or the screw after the glue dries.

Note

For high-quality fasteners, in addition to well-chosen anchors, it is equally important to choose the right size screws or bolts, that he, without breaking the dowel, tightly held structure. For spacing of dowels is the most optimal is the use of screws. Their size should be chosen taking into account the thickness of the attached surface.

Useful advice

The hole in which the dowel is hammered, must be cleaned of dust and debris around him should be free of cracks and chips.