You will need

- Panel, insulation, glue, press, knife, protective coating.

Instruction

1

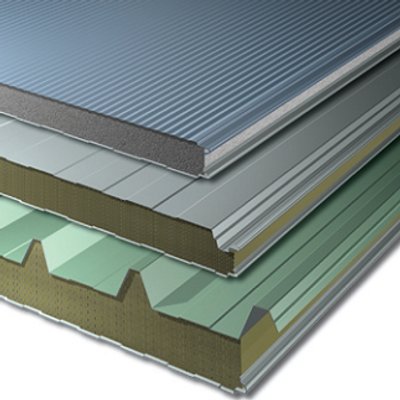

Make your choice for the extreme layers of the sandwich panel. It can be galvanized steel, chipboard, aluzinc, plastic, OSB and even wood. The minimum thickness of each sheet should be 60mm. Any material has its drawbacks and its advantages. For example, the tree more ecological, but it is harder to work with, it is less durable and more fire. Galvanized steel does not burn, but can rust without special processing and deflection.

2

Select the insulation that will be in the middle. The intermediate layer can be polyurethane foam, polystyrene foam, basalt fiber or mineral wool. The width of the insulation depends on for what purpose you are building a building. If it is a summer house, the filler may be 1-2 cm If you plan to stay in the building even in the winter time, then make the filler more than 3-5 see

3

Apply a protective layer on one side of each panel, which will be located at the edges. Protection pick, based on the material panels.

4

Allow to dry panels. This should leave at least a day. If you have applied several layers of protection (this is mainly for wood panels), then increase the time to three times.

5

Apply glue to the other side of the panel you are covering for protection. Glue is best used on a polyurethane basis. Carefully place a layer on the panel.

6

Apply glue to the second panel. Turn it over and place on a layer of insulation. Form a panel.

7

Place the sandwichpanel under a press for 2 or 3 hours. Press should be placed on the whole surface of the panel.

8

Leave the finished panel to dry for 15-30 hours (depending on materials used). Then a sharp object cut away the excess insulation, if any.

9

Cutting panels into sheets of the desired shape. Your sandwich panels are ready!

Note

Apply glue to the entire surface of the sandwich panels, or they can delaminate.

Useful advice

If you use corrugated panel make the insulation fit well in all areas of the product.