You will need

- - splays;

- - lint-free cloth;

- - alcohol;

- - fiber cleaver;

- - special welding machine;

- optical tester.

Instruction

1

For the mechanical joints will need to splice in the body of which is entered through the channels of the cleaved ends of the optical fibers. First of all, they must be cleaned and degreased. Shell remove the stripper buffer layer. Moisten a lint-free cloth with alcohol and clean it the ends of the fibers. Then, cleave the fiber end face at an angle of 90° with the aid of a tool – breaker.

2

Finished all enter through the side channels of the splice with the different parties in the chamber, which is filled with an immersion gel. Introduce fiber to mutual contact. Cover the splice after the closure securely fasten the connection. Install the assembled splice on the splice plate cross or clutch along with the process supply of fiber. Check the connections using time domain reflectometer or an optical tester.

3

Another method of connection of optical fibers welding. For it you need a special machine containing a microscope, clamps, arc welding, microprocessor and shrink oven. Prepare the ends of the fibers to weld the same way as prepare them to mechanical connection, removing them from the shell. On one end put a heat shrink sleeve that will protect the place of welding. Then, as indicated in the first step, make the degreasing and chipped ends.

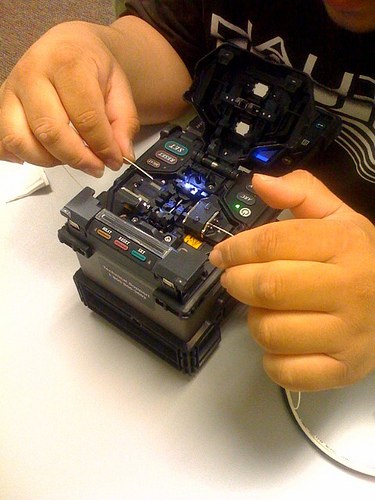

4

Place the fiber in a welding machine in which they are aligned. Automatic machine justeret fiber, making a chip and receiving a confirmation from the operator, will produce welding. If the apparatus has no such functions, these operations must be done manually. Rate the quality of welding optical time domain reflectometer. This device will allow to identify the degree of damping and inhomogeneity. Slide the protective sleeve to the welding spot and set the heat shrink oven. When the sleeve has cooled, place it in a protective splice plate cross or clutch along with the process supply of fiber.