You will need

- - steel stand or bench vise;

- - steel rod (firing pin);

- - support sleeve;

- - hammer;

- - steel ball.

Instruction

1

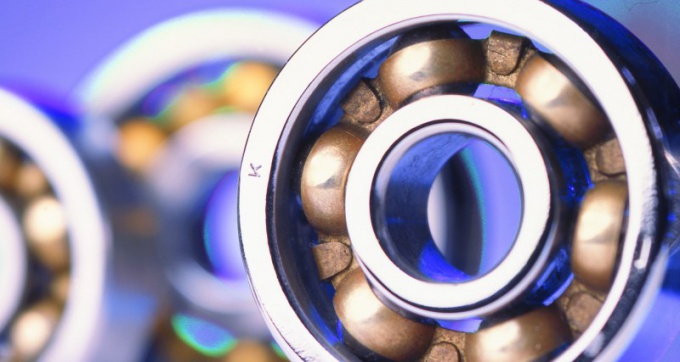

Install on steel kickstand bushing. Its diameter should match the diameter of the sleeve bearing.

2

Put the bearing on the support sleeve, and insert into the top hole of the bushing bearing steel ball.

3

Press the ball with the striker. The firing pin must be made of steel, on the end of the steel rod must be drilled hole for fixing the position of the striker on the ball.

4

Press firmly the construct to direct the force vector straight down. Apply with a hammer a few light punches. The force of the impact will depend on the size of the bearing.

5

Then check how different the play. To do this, in the hole of the bearing, insert the axle of the fan and wiggle it in different directions to the axle tightly enough into the hole.

6

As soon as the axle snaps into bearing at a depth of 2-5 mm (depending on the size of the bearing), start to roll the axle hole, performing circular motion. Ensure that the axle is not rotated in the sleeve, and "rolled" the inner surface.

7

Complex repeat the above actions several times to achieve minimum backlash at the time of free rotation of the bearing.

8

The inner surface of the sleeve bearing will be reduced, to ensure smooth rotation of the bearing is necessary to apply grease of high viscosity. Its density will allow to achieve correct operation of the bushing.

Note

The working surface of the bearing axis has a smooth (specular) surface. If it was formed roughness or scratches, and the bearing during operation, makes a lot of noise, most likely bearing a large backlash.

Useful advice

To achieve higher accuracy when performing recovery of the bearing, use a more accurate special equipment.

In some cases, to restore normal operation of the bearing well enough to lubricate the working (internal) surface of the part.

In some cases, to restore normal operation of the bearing well enough to lubricate the working (internal) surface of the part.