Instruction

1

For the manufacture of backgammon use valuable hard woods – such as oak. Find a reliable supplier of quality and saved all the rules of the oak boards, and purchase a Board thickness of 5 cm Buying unseasoned boards, you assume the responsibility for their further preparation for processing.

2

Dry the boards in a drying chamber, if you have one; if not – buy the already dried boards from companies that have their own drying equipment.

3

Sawed boards into thin boards, from which you later will collect a flat shield that would become a play field. Separately to saw thin narrow boards that will become the frame for backgammon.

4

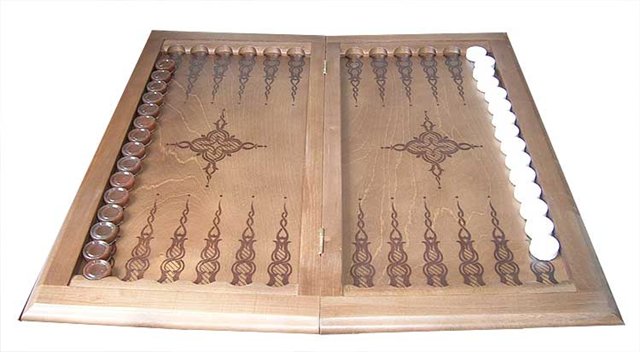

On the outside of the wooden box will look beautiful carved pattern. If you have the skills of carving, can make your backgammon even more unique, creating a pattern of threads by hand.

5

If you have access to a special milling machine – run the thread with it. Unlike manual work, the machine helps to create many of the same elements of the pattern.

6

After the frame and the playing field will be ready, cover them with protective impregnation, stonerose and varnish. Then go over all the wooden surfaces of backgammon with a grinding machine and again varnish.

7

Collect backgammon and leave them to soak for a few days that the Board "used" to each other. After some time modify the backgammon game field cover need paint, finish sanding, varnishing and tinting.

8

After the last painting wait a few days to Polish is fully absorbed into the wood and dry. Place inside the box with backgammon chips and dice are ready and the game can be presented and used as intended.