Instruction

1

At the end of any die has to be crammed stamp reflecting the necessary information. Note the steel grade of the dies and thread designation. The thread is left and right, so that the brand can meet the appropriate letter symbols ("R" or "L"), indicating the direction of the thread.

2

If you need to cut threads in a pipemade from high-strength stainless steel, then you will need a die of appropriate diameter marked R18. Even better to use the die marked R18F2, where "F2" denotes that the tool steel contains up to 2% vanadium acts as an alloying additive. In the absence of the listed dice will fit steel die stamps P9, which is quite common.

3

The dies can also be cut or uncut (solid). The first will allow you to achieve precision, by passing the thread in several passes with parallel adjustment of the thread diameter with the locking screw knob.

4

This files most often for threading the pipes are used round dies, although for threading manually often use a sliding die, fixed in a special oblique die stock and having numbers from one to six.

5

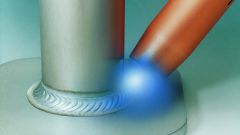

Want to know how to cut thread? It's not difficult. Take any driver, it pick up the die for cutting the desired thread on the pipe of the necessary diameter. Insert the die into the ratchet and secure it there by tightening the bolts two or three sides. The tube should hold in a Vice, wrapping it if necessary, something soft (such as cloth). Install the die to the pipe end and start to rotate, simultaneously pressing: start to cut carving. After reaching the desired mark, simply Unscrew the die back. If the die is a little tight going back again scrolling to the end of the thread, turning it back and forth a few times in particularly difficult areas. That's all.