Replacement of the timing belt is most conveniently carried out by installing KIA SPECTRA in the pit. You will need a set of carob and spanner wrenches, flat screwdriver, pry bar, pliers and automotive lamp. Naturally, you first need to purchase a new belt and tensioner pulley.

To have access to the site, you will need to remove the decorative cap and the casing of the timing belt. It is secured by two upper and two lower bolts that need to Unscrew and then remove the mounting bracket engine cover. You will also need to remove the bracket dipstick for measuring oil level. After this, the upper part of the casing can be removed to obtain access to works at the bottom.

To remove the lower part of the casing, you will need to remove the pulley on the alternator belt and pump the GRU. The vehicle is in fifth gear and the Parking brake. Pulley fixed with one bolt with the right thread that you want to disrupt one sharp movement. After the pulley is removed, you can remove the bottom part of the cover. You then loosen the bolt on the tension pulley and took his hand, loosen and remove the belt, then you can proceed to placing pulleys on labels.

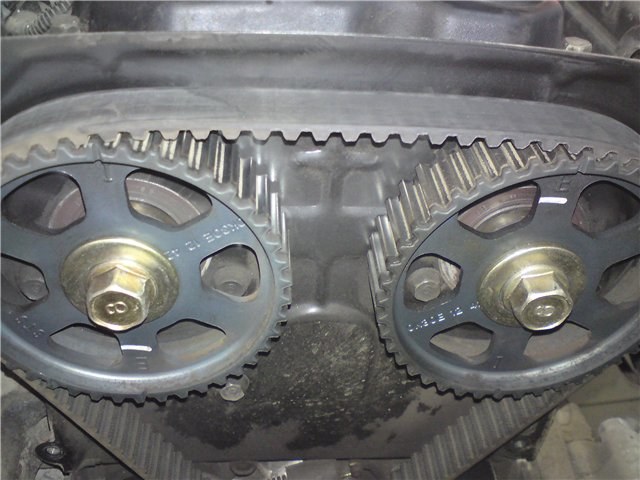

The most convenient way to combine tags to post the right front wheel of the car and rotate it. Marks on intake and exhaust pulleys have the form of the embossed letters "I" and "E" respectively. They should be aligned with the corresponding marks on the metal camshaft cover.

In this position, the timing mechanism is set in the ignition timing of the first cylinder, respectively, the cylinder should be set at top dead center of the compression stroke. This can be done by tags, which are deposited on the pulley of additional units and on a special ledge next to him. Labels have the form of small notches.

A new belt is installed when issued and allotted marks stretch roller. Crank pulley timing should not, in case of discrepancy the teeth can be customized to the desired position the crankshaft pulley. When the belt is installed, you need to give the full tension of its leading branch, and the slack removed with a tension roller. To do this the crankshaft must rotate two turns, spinning wheel posted: spring roller itself establish the requisite degree of tension.

After all the roller needs to be tightened, install the lower portion of the housing, alternator pulley and the GRU, the upper part of the casing and the mounting brackets.

Access repair

To have access to the site, you will need to remove the decorative cap and the casing of the timing belt. It is secured by two upper and two lower bolts that need to Unscrew and then remove the mounting bracket engine cover. You will also need to remove the bracket dipstick for measuring oil level. After this, the upper part of the casing can be removed to obtain access to works at the bottom.

To remove the lower part of the casing, you will need to remove the pulley on the alternator belt and pump the GRU. The vehicle is in fifth gear and the Parking brake. Pulley fixed with one bolt with the right thread that you want to disrupt one sharp movement. After the pulley is removed, you can remove the bottom part of the cover. You then loosen the bolt on the tension pulley and took his hand, loosen and remove the belt, then you can proceed to placing pulleys on labels.

Combining marks

The most convenient way to combine tags to post the right front wheel of the car and rotate it. Marks on intake and exhaust pulleys have the form of the embossed letters "I" and "E" respectively. They should be aligned with the corresponding marks on the metal camshaft cover.

In this position, the timing mechanism is set in the ignition timing of the first cylinder, respectively, the cylinder should be set at top dead center of the compression stroke. This can be done by tags, which are deposited on the pulley of additional units and on a special ledge next to him. Labels have the form of small notches.

Install a new timing belt

A new belt is installed when issued and allotted marks stretch roller. Crank pulley timing should not, in case of discrepancy the teeth can be customized to the desired position the crankshaft pulley. When the belt is installed, you need to give the full tension of its leading branch, and the slack removed with a tension roller. To do this the crankshaft must rotate two turns, spinning wheel posted: spring roller itself establish the requisite degree of tension.

After all the roller needs to be tightened, install the lower portion of the housing, alternator pulley and the GRU, the upper part of the casing and the mounting brackets.