You will need

- - Jack

- - wooden support.

Instruction

1

In order to verify the technical condition of these parts of the engine, the car, which previously dismantled the crankcase, installed on flat ground.

2

Then, lifting on a Jack any front wheel, along the center of the pallet of the engine, a wooden prop in the form of small cut logs. The machine is lowered and the Jack removed.

3

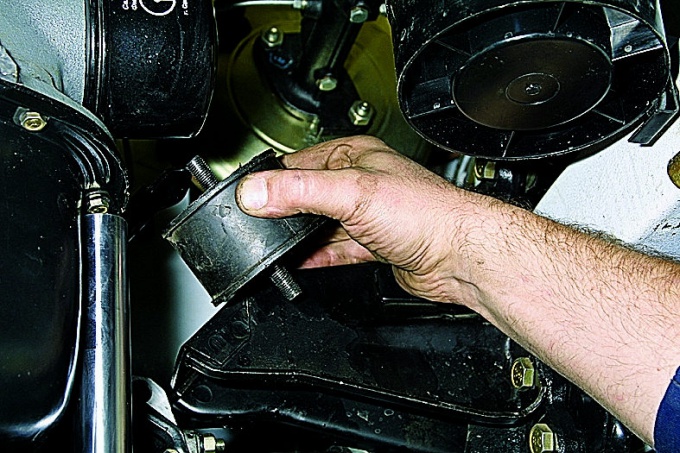

Slightly hung out of the engine, visual inspection revealed: the presence of cracks in the cushions, place of curing rubber, as well as the presence of peeling of metal parts from the rubber base.

4

As shown, the majority of pillows of the engine there is a rupture of elastic components in the mid-section.

5

By visual inspection, and, finding the aforementioned shortcomings, there is a check backlash mounts engine mounts to the body or the front beam of the car.

6

For the assessment of the reliability of the engine is deflected in different directions with a tire iron. In cases of detection of unacceptable backlash in the joints of pillows with a body from under the tray motor is removed the previously installed wooden column, and then fastening the supports of the engine are tightened with a wrench 17 mm.