Instruction

1

Conduct pre-training disks. To do this, follow the sanding and polishing. Get the perfect surface, because after the chroming all the faults and flaws will be more noticeable. After polishing degrease the surface. Use organic solvents or alkaline solutions, which must initially be heated. Give this stage particular importance, it depends on the durability and quality of chrome plating applied.

2

Apply to the volume, the binder layer of the soil, which after drying, leave on the surface of a translucent vitreous cover. Be careful to avoid drips. Layers can be several, it all depends on how quickly the surface becomes evenly covered. Wait for complete drying of the soil, which is about 1-2 hours at a temperature of 60-65°C. At home you have to wait about 7-8 hours. If the item is complex, the metallization need only the following day after priming.

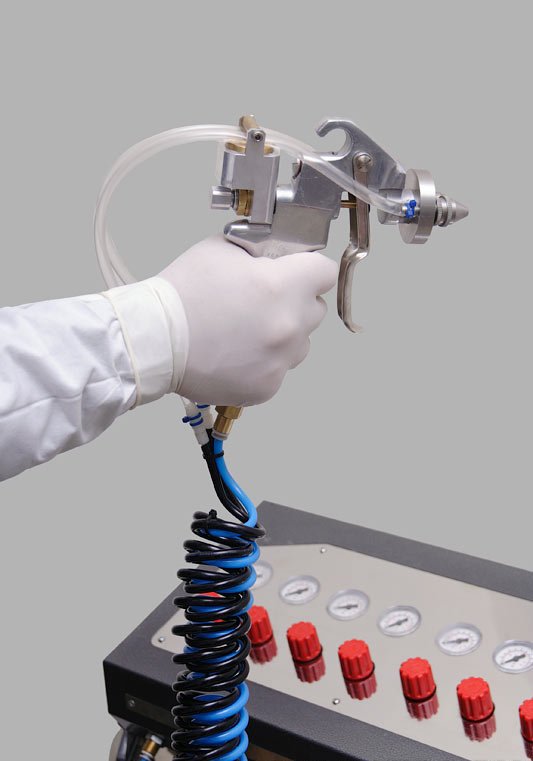

3

With a special spray gun swipe rinse the product with distilled water. Then apply a special solution on the disc that mixes the reductants and chromium, and rinse again. Start plating with the lower portion and move to the top as the formation of mirror coating. The remaining water, remove with compressed air, use air gun.

4

Dry the item for half an hour at a temperature of 40°C and at room temperature, the drying time increases to 3 hours. After that, apply several coats of protective varnish. The first layer are raspylenie for their application, use a small amount of the composition. Add the paint in a certain proportion of the coloring pigment toners, to give the drives the appearance of copper, bronze or gold. Remember that you need to apply another coat of protective varnish.