You will need

- 1 method - level wooden bar thickness of 25-40 mm, width 50-80 mm, length 150-200 mm, sandpaper 120-150 units;

- 2 way - 2 special round grinding bar;

- 3 way drill (drill press table) and fixture for holding knives to the grinding circle.

Instruction

1

To use the first method you need to upholster the top of the wooden block with sandpaper, then rubbing, pressing evenly around the edges, cutting part of a knife or a grid on the sandpaper, periodically checking the contact patch with her knife or mesh. The knife is considered sharp, if the contact patch evenly and without gaps spread on all surface of a knife or mesh. This method is the simplest, but it maleffects.

2

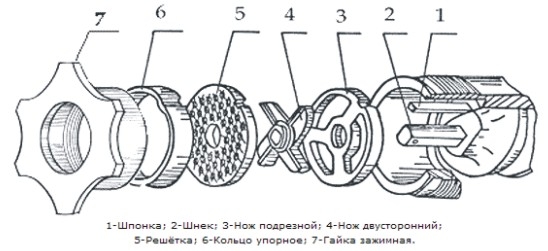

More efficient second method. The kit for sharpening knives grinder includes two grinding round bar. One is uniform in thickness, has a semi-circular rim on the outer edge (like the grid) and round hole in the center is the detail for sharpening a knife, the second bar of smaller diameter has a square hole in the center (as in the knife), its thickness decreases from the center to the edge - this one is for sharpening the grid. You first need to assemble the grinder with the first bar instead of a grid, sharpening to produce, by turning feed screw clockwise only, achieving a uniform and complete contact of the working surface of the knife. Then need to assemble the grinder by installing the second bar instead of a knife. Sharpening to produce as with the first bar. The diameter of the contact patch should be slightly greater than the diameter of the knife and evenly surround the openings of the mesh.

3

The most effective is the third way. In the Chuck of a drill (drill press table) is inserted wrockwardine device whose middle part should be slightly smaller than the Central hole of the grid and extreme are inserted into the lateral holes of the grid. Sharpening must be done, turning and pressing this device grid to a horizontal (lying on the table) silicon carbide circle. The surface of the circle should be smooth, without ditches and mounds. Speed - no more than 300 - 400 rpm. The surface at the site of contact of the circle with a grid or a knife must be constantly moistened with water, otherwise there is a risk to burn the mesh or knife. The drill must be kept perfectly vertical! For sharpening a knife you use a different device, which is an iron rod with a diameter of 12-15 mm, with one edge planed square 8 by 8 mm, which is inserted into the knife. Attention! The drill needs to keep vertical, otherwise the knife or mesh will tend to leave the circle. If you have no relevant skills, use a lapping machine or the second method.

Note

Sharpening of the mesh, otherwise even with a new knife grinder will not work.