Instruction

1

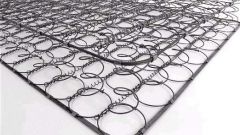

All springs depending on length and load 3425 N (350 kgf) is divided into two classes: class "A", the length of which is more than 278 mm and class "b", the length of which is less than or equal to 278 mm. In this case, coil springs "class b" on the outside of the coils are painted over with black paint, and a class "A" is not painted over at all.

2

Before testing, all parts should be thoroughly rinsed. Sleeve, protective coatings and rubber parts don't forget to protect from solvents. Then inspect every detail of the springs for cracks, mechanical damage and wear.

3

You need to check the length of each of the rear springs or front suspension in a free state, if the length of the spring is less than the maximum allowable standard value, then it must be replaced. Remember that the standard is equal of 44.00 mm length of a spring under a load of approximately 216 H of 35.00 mm and the length of the spring under load 451 N is 27,20 mm.

4

Now test the elastic characteristics of the spring itself by its control points, before tentatively holding it to the contact of the turns with each other. Then see whether there is deformation of the rear springs or front suspension, if it is, then it means that there is a reason its performance, so you need to replace the spring.

5

Then you should check spring for Squareness. If any crooked areas exceeds the upper limit standard value is 1.5° or less, it means that the spring has broken its properties and should be replaced.

6

There is another old method of checking springs. For this between two metal straps with bolts in the middle should hold the old and new springs and gradually tighten the nut of the bolt. If they are compressed to the same extent, so that the old spring is in good condition.

7

And finally, check the condition of the rubber support pads springs, rear or front suspension. In case of malfunction replace them with new ones.

Useful advice

If you need replacement springs, they should be replaced at the same time on both sides of the car.