You will need

- cable, coil, aluminum emxt, dibutilftalat

Instruction

1

Prepare a few of the high-voltage two or three wire cables, which can be found at the dump, in the areas of buying metals or manufacturing plant cables.Purchase braid white or black. Braid and the cable are made of plastic, so you can find it on the relevant plant or on the construction market. Braid is the most appropriate, because the forms are produced from high quality, waterproof, durable and strong, which can be cast not only plaster casts, but also cement-sand mortar.Prepare dibutilftalat is a special yellowish liquid, which can be purchased at a hardware store or plant for the production of cable.

2

Rinse the braid or cable hot water and cut them into small pieces (approximately 3 cm).

3

Prepare an aluminum container for cooking and a spoon of the same metal. Remember to take the capacity of another material is not necessary, as your mixture will stick to the walls, and it is unlikely you will achieve the desired result.

4

Place 800 grams of cables or braids in the form of melting, add 1 liter dibutilftalata. Wear a respirator and turn on the hood.

5

Prepare a container of machine oil, a couple of which will cook our product. Place the container on a regular electroplate.

6

Insert in a container of oil aluminum pan with a braid. Bring to a boil, gradually stirring with a aluminum spoon. In the case that coalescence and adhesion of a substance to contribute to the capacity little by little dibutilftalata. This can be done only when necessary.

7

Cook at a temperature of at least 125 degrees for about 7 hours. The bubbles should be solved forever. The formoplast should be similar to plastic. You should know that the temperature during melting should not raise over 140 degrees, as this may lead to rasliani substances.

8

Strain the resulting stock through a brass mesh No. 2. This must be done in order for the lumps, if any, have been eliminated.

9

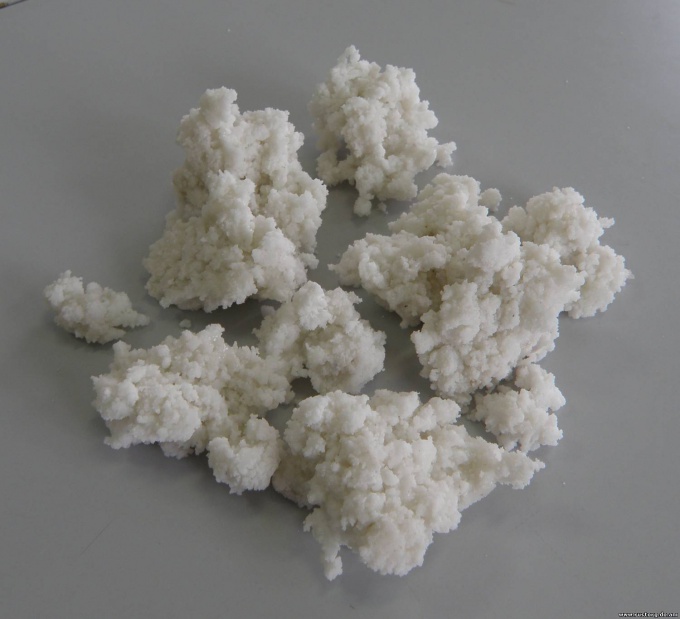

Pour the molten liquid into a prepared sand form, allow to harden.

Formoplast is ready.

Formoplast is ready.

Note

The disadvantage of formoplast, is its strong toxicity during melting and production of substances, therefore, all actions with this material should be made, strictly observing the safety regulations.