You will need

- Clay, graphite powder, welding machine, iron barrel,any non-residential premises.

Instruction

1

Locate non-residential premises, garage or shed. It must be the power source for further work.

2

Aluminium is extracted from bauxite. Go dig in the woods, a field or any career on clay. 100 kg of clay is from 30 to 70 kg of aluminum. Dry it in the sun or with any drying apparatus. This is required for follow-up.

3

The clay should be crushed. For this it is put in the mixer. You can put clay on any surface and grind any heavy object. If it's a little, use an ordinary household grater. It is important that the clay was completely dry. Blend until until it's powder. Of it much easier and faster to produce the metal.

4

Mix the clay powder with the graphite powder. It can be purchased at any hardware store or market. Graphite is required to improve the structure of the aluminum. He is a very good conductor of current. The amount of graphite powder depends on how conducted you want to do aluminum. If the metal you need for any works with energy, add graphite at the rate of 20 kg per 100 kg of clay. If nothing else, take 10 lbs.

5

Pour the mixture powder into a large iron barrel. Cover with water. Humidity should not be less than 75%. Water is a good conductor of current, and therefore the manufacturing process will go faster. With the help of a welding machine or any other powerful device apply tension to the barrel. Be very careful. Do not touch the barrel, especially with wet hands. Thanks to the powerful current and the graphite powder in 5-8 seconds happens release of oxygen from the clay and formed aluminum alloy. The source of the electricity must be turned off.

6

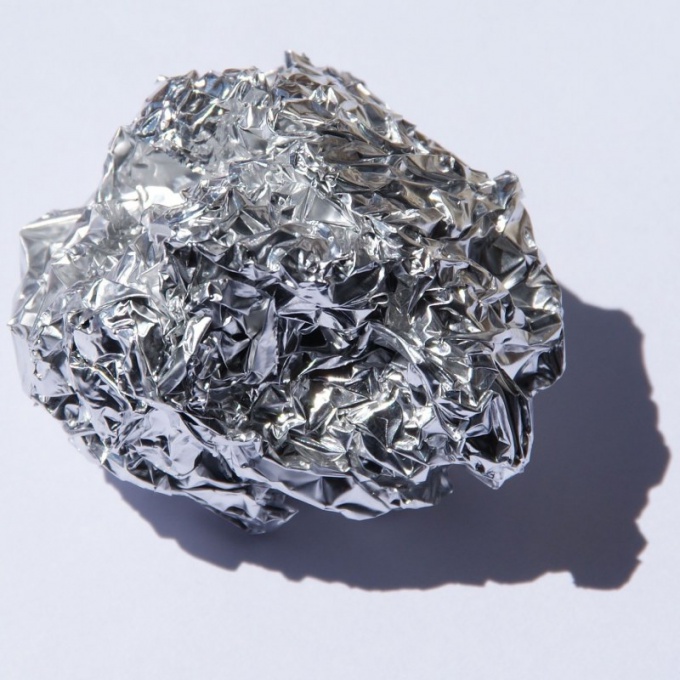

Leave the barrel for several hours to cool sufficiently. Remove the lumps obtained in the process. This is the alloy. It can be cleaned, or to leave them in this form.

Note

Clay will not clean aluminium and its alloy.